What Can You Do with Geomagic Freeform?

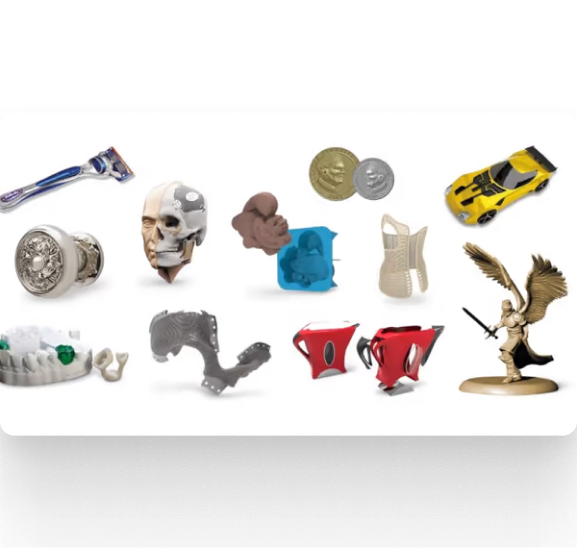

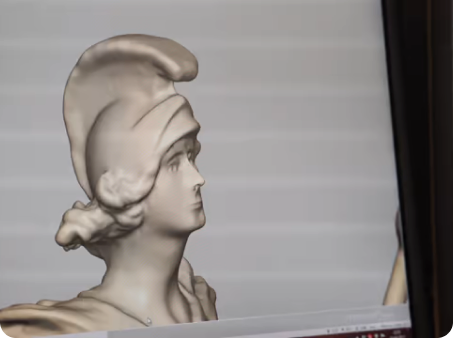

Customers are using Geomagic Freeform for a wide range of applications—from large-scale, customized products to highly-detailed, ornate, and artisanal products—across a variety of industries.

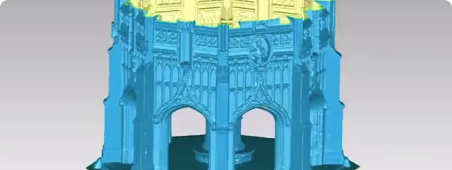

- Creating fast design and reiterations of intricate models in minutes.

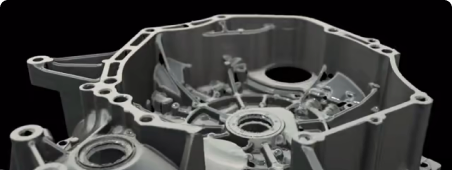

- Designing manufacturing-ready models from multiple file formats combining solids and surfaces.

- Defining complex parting lines, removing undercuts and overhangs, and adding finishing details.

- Repairing complex geometry no matter the origin design software.

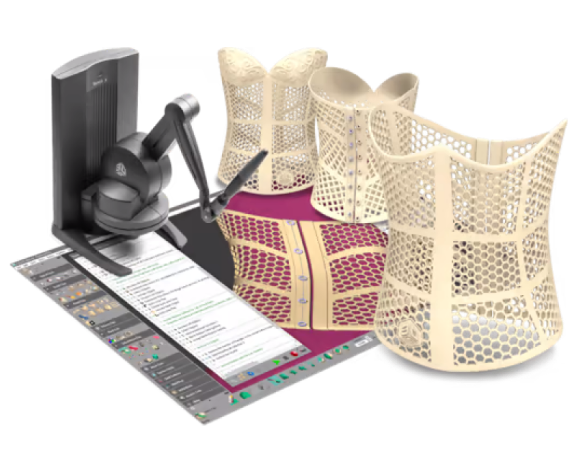

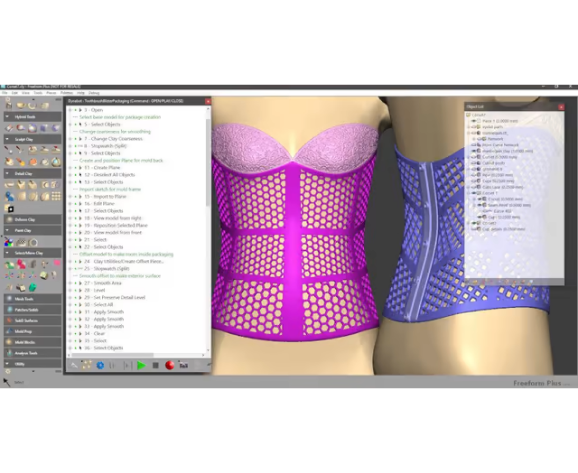

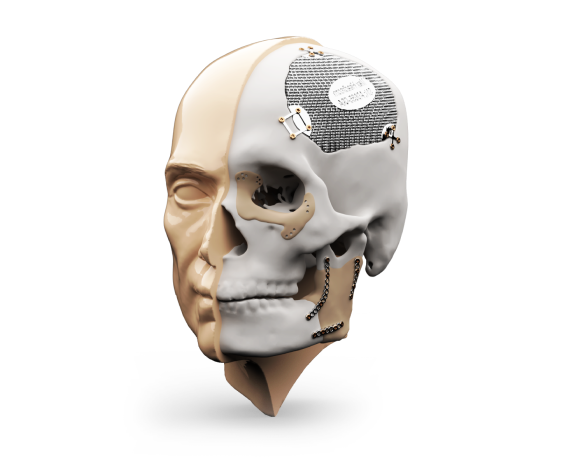

- Transforming traditional hand fabrication of orthoses and prostheses (O&P) to a digital workflow.

- Designing custom orthotics and prosthetics that are highly-personalized, better-fitting, lighter, and stronger.

- Innovating and personalizing their artisanship with precise, multi-material, engineering-grade manufacturing processes.

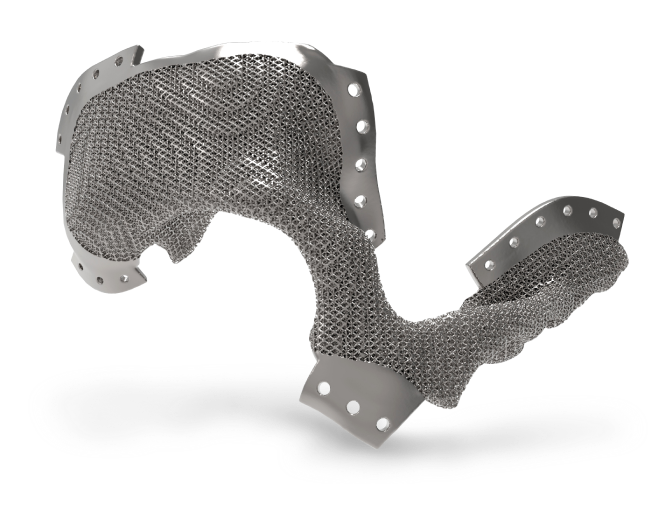

- Creating functional cages for applications such as custom medical implants.

*Geomagic Freeform is not a medical device and Oqton makes no claims that it is intended to treat, plan, or diagnose. However, there is evidence and publicly-available research that indicates many customers are successful using Geomagic Freeform in their own patient-specific solution workflows and are following all local regulatory requirements.