All-In-One Industrial Additive Manufacturing Software

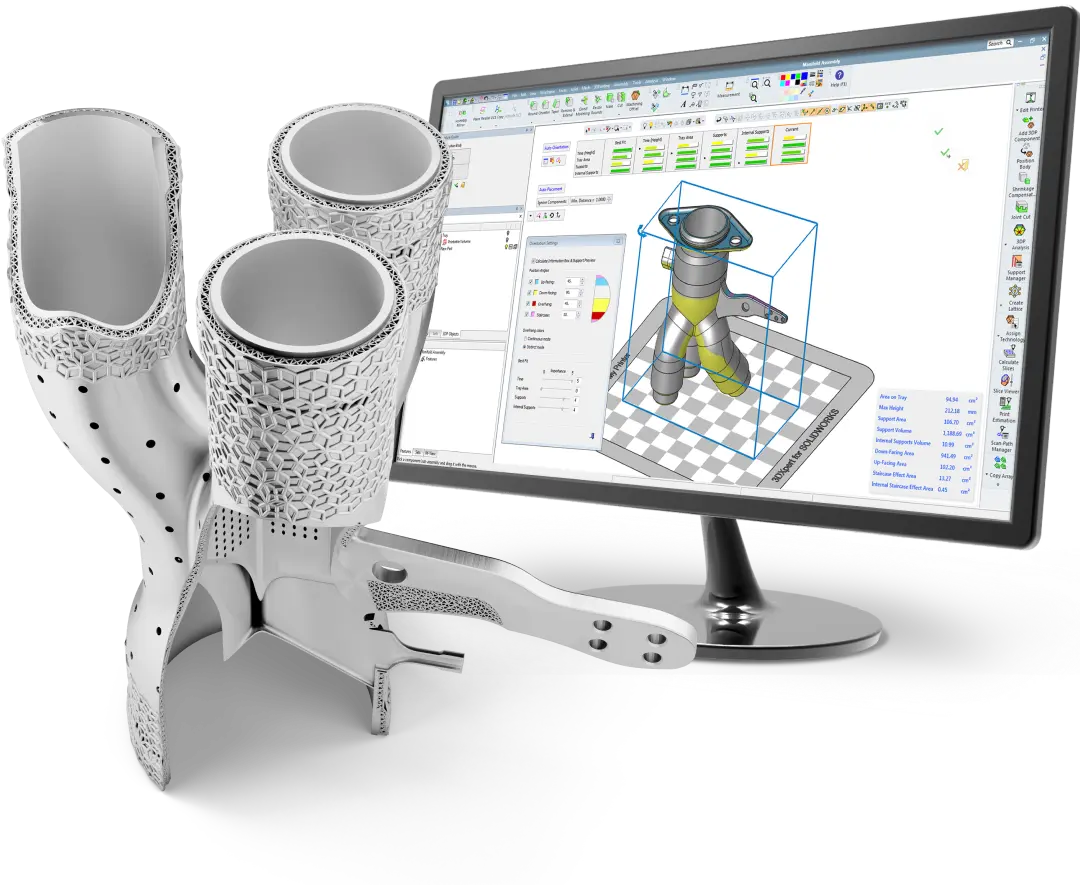

Prepare, optimize, and 3D print high-quality parts in record time with 3DXpert, an all-in-one, integrated 3D additive manufacturing software that streamlines the complete workflow, from design to printing.

Design. Prepare. Build. Inspect.

3DXpert is the complete software solution for additive manufacturing, from design to printing. Quickly and efficiently transition from a CAD model to a high-quality, 3D-printed part.

3DXpert is the best solution to support the disruptive shift from rapid prototyping to serial AM production.

- Hybrid DfAM & Applications

- End-to-end parametric Build Prep

- Process Simulation

- Automation

- Inspection

Design for Additive Manufacturing

Maximize Part Performance

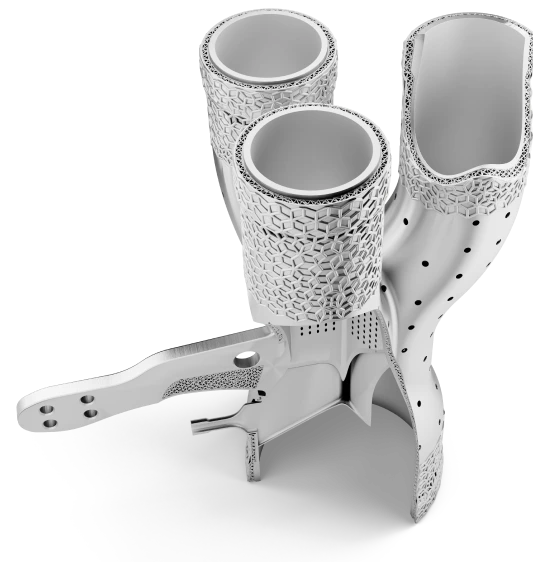

3DXpert provides a dedicated design toolset required for light-weighting, texturing, and printability modifications. Constructed with manufacturability in mind, 3DXpert puts the M in DfAM.

- Topology Optimization

- TPMS and beam-based lattices

- Texturing

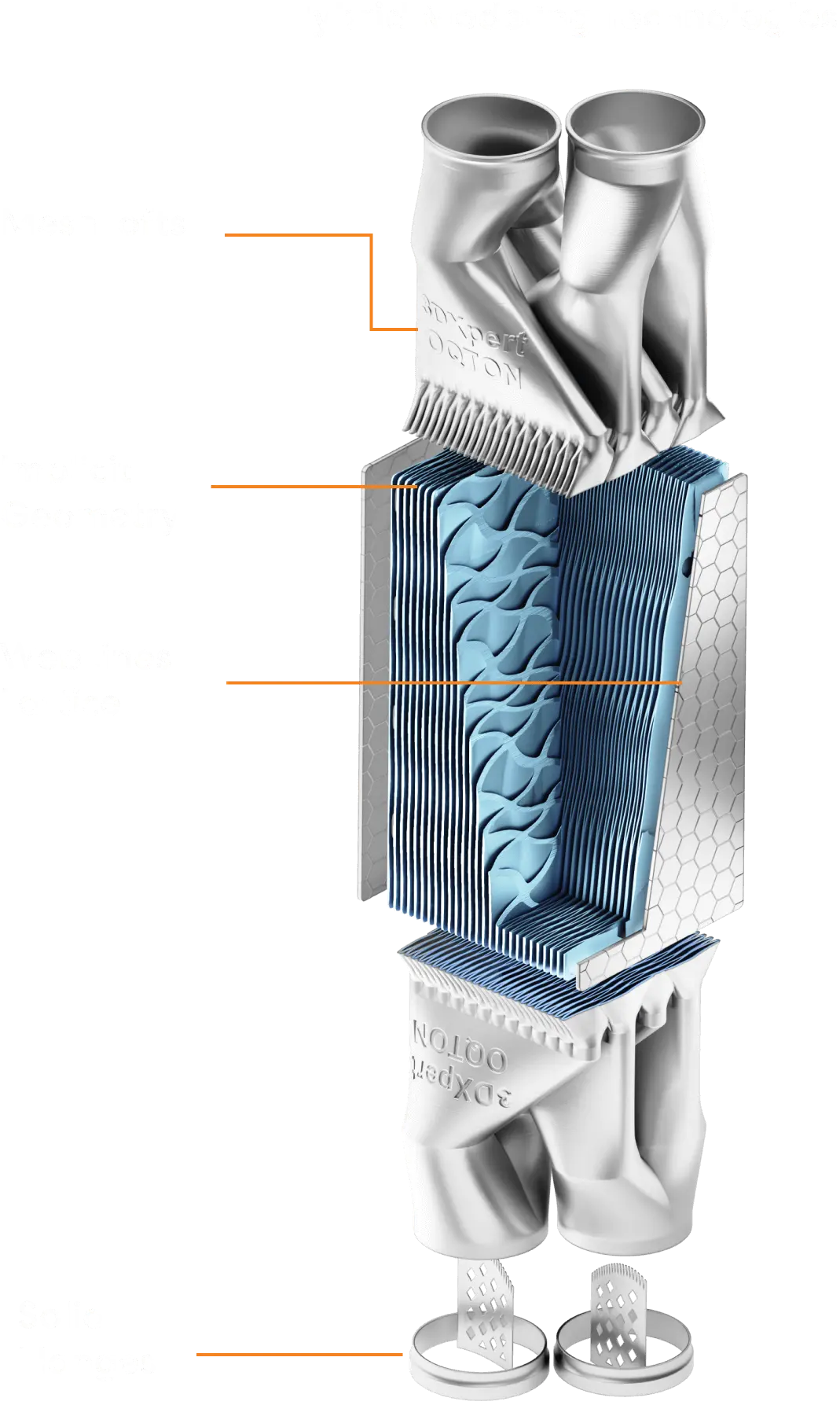

- Conformal cooling & Manifold Design

- Implicit Modeling

- Dedicated Heat Exchanger Design application

Build Preparation and Slicing

Minimize manufacturing costs

3DXpert helps you keep the relatively high costs of 3D printing as low as possible. Reduce tryouts in your way to your first article, avoid costly mistakes, and optimize your printing process. With complex parts, 3DXpert gives you peace of mind.

- Decision support Process Simulation - avoid failed builds

- Single environment - avoid costly errors in file transfers

- Orient, nest, support, arrange, slice, and optimize

- Save time and errors through automation

- Reduce material consumption

- Cost estimation and reports

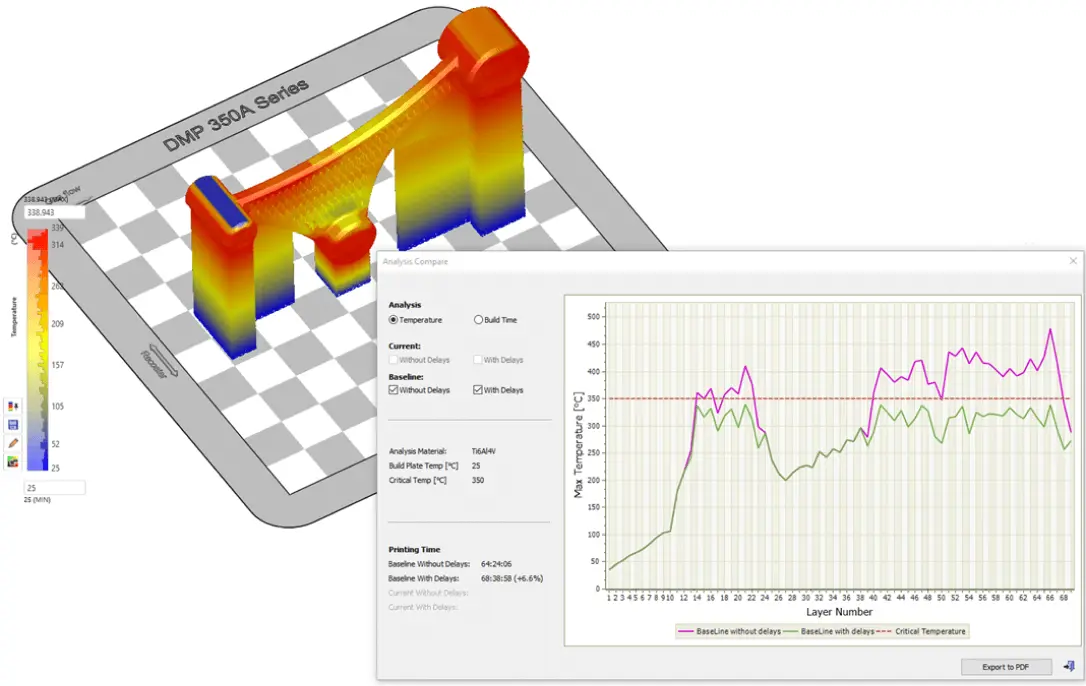

Simulate & Compensate

First Time Right

Process simulation anticipates the conditions and events taking place within the build chamber, indicates potential build issues, and allows for automatic pre-compensation of predicted displacement. If you do see deviations in the printed part, 3DXpert can read 3D scan data to provide a scan-based compensation.

- Structure (mechanical) Simulation - predict failures and deviations

- Thermal Simulation - ensure thermal stability

- Simulation-based Compensation

- Scan-based Compensation

Industries

Additive Manufacturing Software For Every Industry

Manufacturing

Handle every file format your customers send with parametric, automation-ready build preparation and Supportless enabling strategies.

Energy

Support localized production, spare parts on demand, or transformative concepts like additively manufactured valves or heat exchangers.

Healthcare

Add internal structures and use porosity analysis to accelerate osseointegration of patient-matched, or serially produced implants.

Automotive

Optimize laser parameters for serial production or automate build preparation tasks like support creation.

Aerospace & Defense

Reliably build lighter components and higher performing parts. Create competitive advantage in highly regulated industries, with a cutting edge DfAM toolset.

Engineering

Generative Design, Topology Optimization, Process Simulation, Hybrid DfAM: Dedicated tools for value-added engineering.

Bring Out The Big Toolbox

Capabilities for every additive manufacturing application and process

Import Parts

Import any CAD format, maintain CAD integrity, and analyze for printability.

Position and Modify

Set part orientation with real-time analysis of support and down-facing areas.

Design for AM

Use Topology Optimization, Lattice design, Implicit Modeling, and FEA to lightweight and optimize structures.

Design Supports

Analyze parts to automatically or manually create supports for overhanging regions.

Simulate Builds

Perform end-to-end fault prediction within the design environment to verify part builds.

Optimize Printing Strategies

Shorten printing time and ensure high quality surface finish.

Calculate Scan Path

Optimize slicing and hatching to ensure repeatability and quality.

Arrange Build Platform

Use the operator edition to easily position parts on the tray and send them to print.

Integrated Process Simulation For Additive Manufacturing

Physics-based job preparation tools powered by Amphyon technology

Build Near-Net-Shape Parts

Reduce costly build iterations. Automatically compensate for deformation. With 3DXpert Process Simulation you can achieve a significant increase of dimensional part accuracy for Metal 3D Printing (LBM, SLM, DMLS). Unprintable geometries become printable.

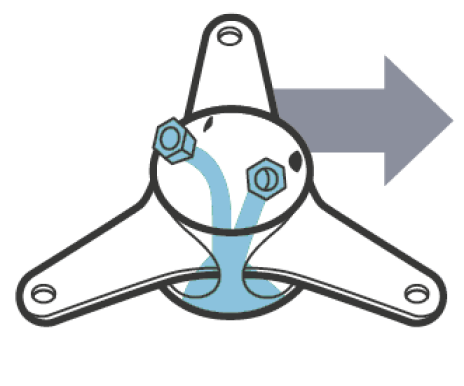

Prevent Printer Damage

The cooling and shrinking that occurs after each layer is printed may cause the metal to rise above the powder bed level. These raised tips can damage the re-coater or even cause the roller to stop its motion.

Use 3DXpert Mechanical Simulation to predict where metal is likely to rise above the next deposit layer and cause damage to the printer, enabling you to take the appropriate corrective action.

No More Overheating

Scaling from one part to a full build chamber changes the whole process dynamics. The Amphyon technology built into 3DXpert utilizes Thermal Simulation to predict overheating and achieve thermal stability by adapting the process setup with layer-specific cooling times - for all types of laser Metal AM machines. Ensure high-quality part properties.

Try 3DXpert additive manufacturing software

Need some more information? Here are some more 3DXpert resources to download.

Don't take our word for it! Have a look at how successful our customers are:

3DXpert FAQs

How can I contact Oqton to request a demo, or purchase 3DXpert?

You can request a demo here, or speak to a member of our team in your region using these phone numbers:

US +1-803-981-6716

UK - +44 1442 279 875

Germany - +49 6105 324 8122

Italy - +39 800 035 847

France - +33 805 10 35 72What languages does 3DXpert support for additive manufacturing?

3DXpert supports the following languages: English, German, Chinese, Korean, Japanese.

How can I request a free trial of 3DXpert additive manufacturing software?

Request a free trial

and fill in your contact details. A member of our team will then contact you. The 3DXpert installation guide can be found on our support site.

What are the minimum system requirements to run 3DXpert?

- Windows 10 Professional

- 4 cores i7 CPU (Gen 9 & above)

- 16GB RAM

- SSD recommended

- GPU - OpenGL enabled graphics card 4GB

- Find full system requirements here.Where can I get technical support for 3DXpert?

Comprehensive documentation is embedded in 3DXpert; you can access it quickly by pressing F1. This works context sensitive and will open the relevant chapter for what you are working on. If you can’t find what you are looking for, you can submit a case to our support team.

What licensing options are available for 3DXpert?

3DXpert is available as a standalone subscription license, ensuring all users have access to the newest features and capabilities. The software comes in different packages

- 3DXpert Basic: Covers all elementary 3D printing tasks, including orientation & positioning, template-based support generation, 2D/3D nesting, slicing, and sending the part to the printer. In addition, it allows for basic DfAM operations – generating lattices and infills, and a full CAD toolset in a hybrid environment including both solid and mesh modelling. It is best suited for polymer powder based processes.

- 3DXpert Standard: The Standard package provides all the tools to prepare and successfully print plastic and metal parts. It includes all functionalities of 3DXpert Basic, coupled with a powerful suite of support generation tools and serial labelling.

- 3DXpert Premium: Advanced Metal AM suite, with all functionalities of 3DXpert Standard, additionally augmented with included GPU-based Process Simulation (mechanical and thermal adaptation simulation of the build process), powerful editing capabilities for build strategies, simulation and scan-based compensation, Automated power Supports and creating and editing of automation scripts.

- 3DXpert Design & Ultimate: A comprehensive toolset for users that require advanced DfAM and Build Prep capabilities. This includes Solid, Mesh, standard Lattice, conformal Lattice, and Implicit modeling design toolset. Designers can use our vast set of dedicated DfAM tools, to apply textures, light weighting, etc. Process Engineers can use all our advanced toolset for build prep to make sure they can directly slice and prepare the AM design for manufacturing, without having to export the geometry to Mesh/STL.

- 3DXpert Elite: Combines all available tools for the most ambitious users. Comes with our complete DfAM toolset (including the Heat Exchanger Application), the 3DXpert Generative Design (Topology Optimization), our complete Part Prep toolset and an integrated Process Simulation for Metal powder bed.

- 3DXpert Educational: Classroom bundle of 3DXpert Elite with all available tools, including a power seat for the professor and up to 10 student seats, for non-commercial use and non-commercial research institutes.

How can I organize a 3DXpert training course?

To organize a training course, please fill in our Contact Us form.

What additive manufacturing machines are compatible with 3DXpert?

3DXpert supports polymer-based processes, as well as metal additive manufacturing. Oqton partners with all major powder bed machine vendors and more (3D Systems, EOS, SLM Solutions, Renishaw, Farsoon, HP, Xact Metal, Aconity3D, Freemelt, etc.) to ensure smooth integration. Contact Us to find out how deeply your preferred systems are integrated..

Which CAD files and other file formats are compatible with 3DXpert?

3DXpert is built on a CAD kernel, and works with a hybrid modeling environment, supporting B-rep (solid and surface modelling) alongside Mesh and Voxels. 3DXpert imports and exports all standard CAD formats. It can directly read native files of common CAD systems: SOLIDWORKS, CATIA, NX, Creo, Solid Edge, Inventor and Rhino. It can also read and write all commonly used generic formats:

- B-rep: STEP, Parasolid, IGES, SAT (ACIS), VDA

- Mesh: STL, 3MF, OBJ, PLY, AMF, 3DXML, JT, VRML

- Voxels: VDB

- Contours and points: DXF, CLI, Point cloud formats