Which Reverse Engineering solution is right for me?

Computer-Aided Design (CAD) has revolutionised manufacturing. Today it’s faster and cheaper to manufacture components than ever before thanks to digital design. But what if you need to replicate a part that doesn’t have a digital data thread?

In many industries, this digital data thread doesn’t exist for integral components, especially for parts designed and manufactured before the invention of CAD tools. Let’s take the railway industry as an example. Many rails were cast up to a hundred years ago, meaning that the only data we have available are the tracks themselves, or the moulds used to cast them.

Here's where Reverse Engineering comes in. It’s the process of interrogating a part or system with the intent of duplicating or improving it. In the world of manufacturing, this involves measuring an existing asset, whether that be a single component or a complete assembly, to obtain the digital information necessary to recreate or improve it.

Let’s go back to our railway example. When the inevitable happens, and a crucial part of the track needs to be replaced, how can we accurately manufacture a new section of rail? How can we ensure that the track not only enables the train wheels to run smoothly but also mates correctly with the surrounding components? With Reverse Engineering we can achieve all of this, but faster than with traditional methods.

Reverse Engineering has always been used in some capacity with a variety of measurement techniques: tape measures, callipers, and even a piece of string! As technology has improved, so has our ability to measure with improved accuracy. The introduction of 3D Scanning hardware has catapulted 3D data capture, making it much more efficient, accurate and repeatable.

But even the best hardware in the world is useless without the right software. For Reverse Engineering, this software should enable you to easily use the data to rebuild, optimise and recreate. There are many options, each with benefits uniquely designed to address real industry challenges. Below, we’ve put together a one-stop guide to our technology, so that you choose the one that suits your needs best.

Click on any of the product icons to learn more.

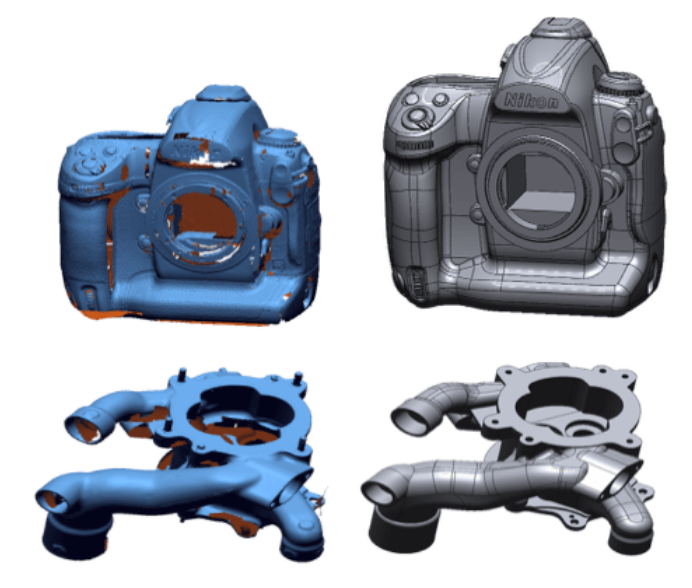

- Creates accurate CAD models from 3D scans, faster, and more reliably than anything else on the market, extracting new business value from existing assets.

- LiveCapture and process huge data sets directly from any scanner within Design X.

- Use both fully automated and guided tools to create complex hybrid 3D models for solids, surfaces and meshes.

- Works just like your CAD tool. Use LiveTransfer to create a complete parametric model with a history tree which can be imported directly into your CAD software, to accelerate time to market.

- The most diverse toolset to enable a scan-to-CAD workflow by anyone, from design novices to seasoned Reverse Engineering pros.

- A streamlined subset of the Design X toolset. With a lower price point, DXE brings the value of Design X to more people.

- Accurate and accessible Scan-to-CAD workflows, enabling users of entry-level scanners to make the most of their hardware.

- Bringing an industry-standard Reverse Engineering tool to anyone, regardless of the scanner, project frequency or design expertise.

- The straightforward path from scan data to CAD, with a full parametric history tree to make design changes.

- Create a usable 3D CAD from “lighter” data sets.

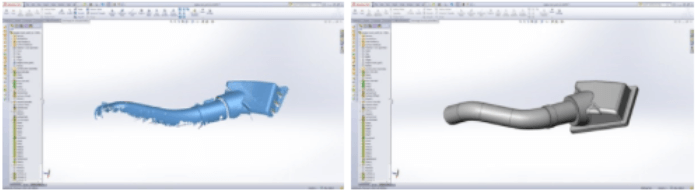

- Geomagic for SOLIDWORKS works just as SOLIDWORKS does, making it very intuitive, quick, and easy to integrate into your workflow.

- Import data or scan directly in SOLIDWORKS and use the integrated, industry-proven feature extraction wizards to extract CAD sketches, surfaces, and solids.

- Ideal for SOLIDWORKS users looking for a straightforward point cloud to complete Solidworks design file workflow, removing non-value-adding tasks to improve time-to-market.

- Delivers the most affordable, fast, and accurate path from point cloud to 3D polygonal models.

- Powerful exact surfacing and cutting-edge modelling functions enable flawless 3D models.

- Ideal when creating that 3D model from complex or freeform scan data, for use in any downstream process, from manufacture to rendering or CFD/FEA.

- Industry-leading scripting and macros to automate repetitive tasks during the reverse engineering process.

- The best intuitive and easy-to-use data acquisition tool for scan processing, optimization, and CAD/polygon creation.

- The industry’s most comprehensive, organic, hybrid design software.

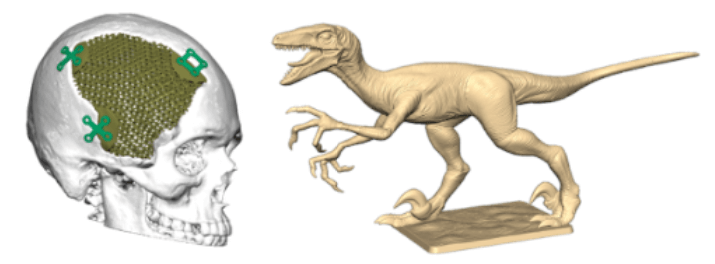

- Geomagic Freeform works with the Touch X haptic device to add a sense of real-world touch to your digital world — delivering freedom of motion and the physical sensation of sculpting in a virtual environment.

- Ideal for artists and designers looking to add aesthetic and functional details and structures that are difficult or impossible in traditional CAD.

- Many users are successfully using Geomagic Freeform to design custom orthotics and prosthetics that are highly personalized, better-fitting, lighter, and stronger, bringing the benefits of a digital workflow to traditional handcrafting.

- Couple Freeform with D2P for unmatched DICOM-to-CAD workflows

Guy Buttle

Guy Buttle