Europe’s leading space systems specialist and Oqton improve shrink line prediction technology and reduce computation time

In the European space industry engineering ingenuity from governmental institutions and private organizations are working towards a joint goal – the advancement of space technology. Additive manufacturing offers many advantages to this area, and system integrators are already using it to produce optimized mechanical parts and even large segments of rockets.

However, to take full advantage of additive manufacturing, the aerospace industry needs to overcome significant process and component-specific challenges. Oqton’s simulation technology for metal additive manufacturing has brought the industry a step closer to this goal with technology that predicts the position and severity of micro-deformations known as shrink lines.

In addition to macroscopic process-induced deformation of an additively manufactured part, thin horizontal deformations may appear on its surface. This phenomenon doesn’t have an official name but is commonly referred to as shrink lines.

In a project funded by the European Space Agency, Oqton, OHB SE and Fraunhofer IAPT collaborated to improve shrink line prediction for additive manufacturing

In a project funded by the European Space Agency, Oqton, OHB SE and Fraunhofer IAPT collaborated to improve shrink line prediction for additive manufacturing

Manufacturers can avoid this issue if they know where the lines will appear. They can modify a design to prevent lines from forming or reposition them away from critical points. These adjustments will reduce time and material use by eliminating unnecessary printing iterations.

Oqton’s team of additive manufacturing process simulation experts improved the shrink line prediction technology in collaboration with OHB SE, a European system integrator in the space industry, and Fraunhofer IAPT, a research institution for additive manufacturing technologies, within a project funded by the European Space Agency (ESA).

OHB System AG, a subsidiary of OHB SE, explores new technologies for spacecraft and satellites. They started working with additive manufacturing seven years ago, and are quickly building a wide range of capabilities in this area supported by an external supply chain.

OHB is the lead partner on AMFLEX, a project that aims to develop and improve the design and manufacturing process for components with 3D-printed flexures. AMFLEX is part of ESA’s General Support Technology Programme (GSTP contract No. 4000138069/22/NL/KML) that converts engineering concepts into useable products by developing the technologies, know-how and capabilities necessary for future space missions.

Shrink lines are particularly problematic in opto-mechanical components where they induce a surface error that results in critical reduction of part quality. Since OHB is developing 3D-printed mirrors for optical instruments, it was a good opportunity to tackle the issue with process simulation.

“One of the first tasks in the project was to find out which improvements need to be made to Oqton's simulation technology so that we streamline the 3D printing of applications that combine optical instruments with integrated thin and flexible mounting features,” Marco Mulser, Additive Manufacturing Coordinator at OHB System AG, explains. “Secondly, we wanted Oqton to implement these enhancements and test them on a real use case.”

OHB plans to incorporate Oqton’s shrink line prediction technology into the design of the opto-mechanical component they will create as part of AMFLEX. “We will use Oqton’s build simulation to pre-calculate the shrink lines, to adapt the design of the mirror and to put the shrink lines on a section that is uncritical for the optical performance,” Mulser added.

Shrink lines essentially represent a notch or a sharp groove. It’s hard to accurately capture the different mechanisms that contribute to their formation on macro and micro level in fast simulations, but we know that they reduce the dimensional accuracy of parts and are a potential failure point. Aluminium and copper – two of the main materials used in aerospace applications – are particularly prone to this type of deformation.

Deformations are common in metal additive manufacturing and existing simulation tools such as Oqton’s Amphyon and 3DXpert predict and compensate them well. However, shrink lines are more difficult to tackle with standard methods because of their size.

The usual solution is to polish the lines during post-processing, but this comes with significant additional costs and sometimes isn’t even possible without altering the part functionality.

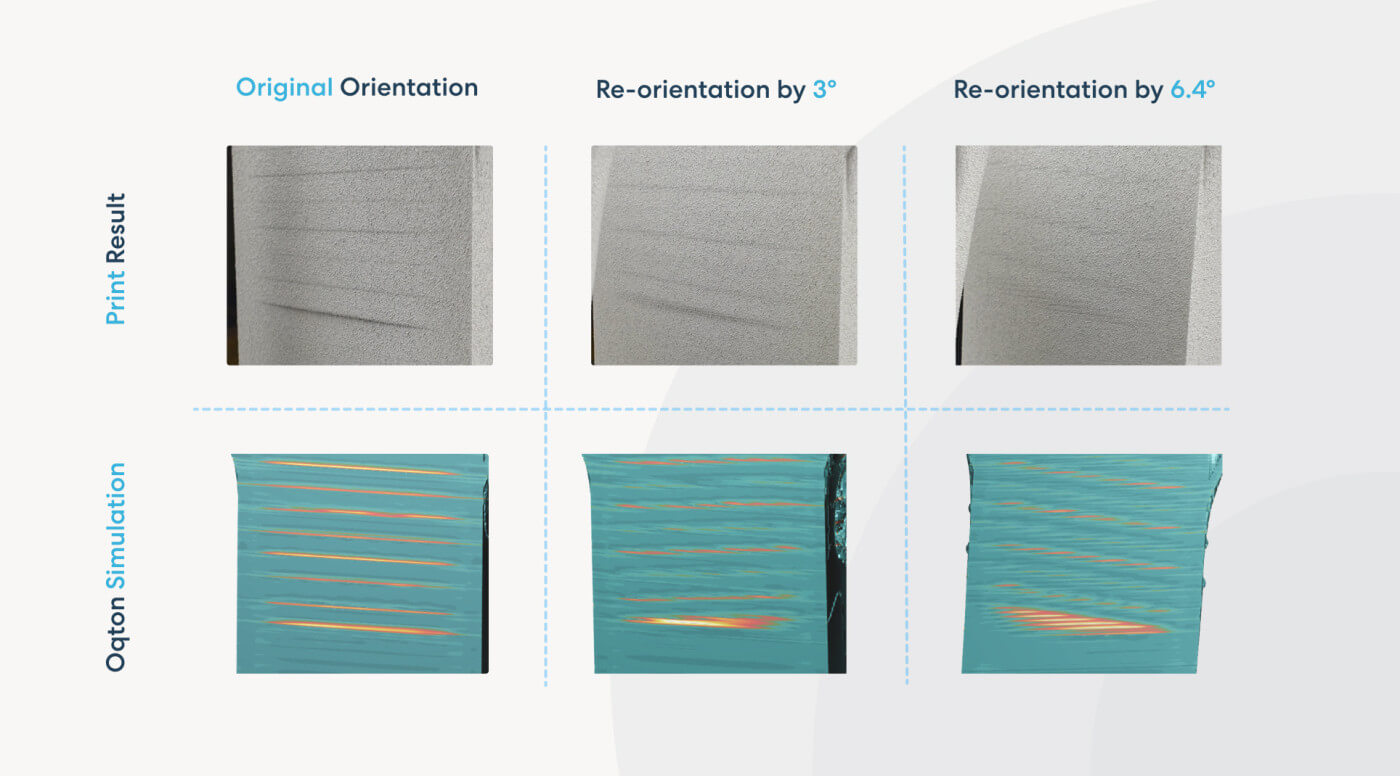

The AMFLEX consortium tested the shrink line simulation on a section of a part designed in a previous project. They simulated three different orientations of the same part on the build plate and found that changing the angle can have a beneficial effect in reducing the impact of shrink lines. The test parts printed by the IAPT showed an impressive similarity with the simulation predictions.

Changing the angle of the part on a build plate can reduce the impact of shrink lines

Reduction in calculation time

As part of the AMFLEX project, Oqton’s team also reduced the computation time of their simulation kernel Amphyon, significantly improving efficiency.

In process simulation, a numerical representation called the finite element mesh is created by dividing a complex object into smaller parts. The number of finite elements determines the computational efforts for the simulation.

Some parts have a big volume, for example 10,000 cm3, but features as thin as 0.4 mm. Dividing the whole part into finite elements with an edge length of 0.4 mm would result in over 156 million finite elements and more than 468 million equations to solve in each stage of the mechanical simulation of the build process. Simulating this kind of numerical problem requires massive computation effort and time.

To ensure fast simulations, the overall number of finite elements within the mesh should be as small as possible and elements as large as possible. On the other hand, certain regions of the part, such as thin walls, require smaller elements to retain a high degree of detail and accuracy.

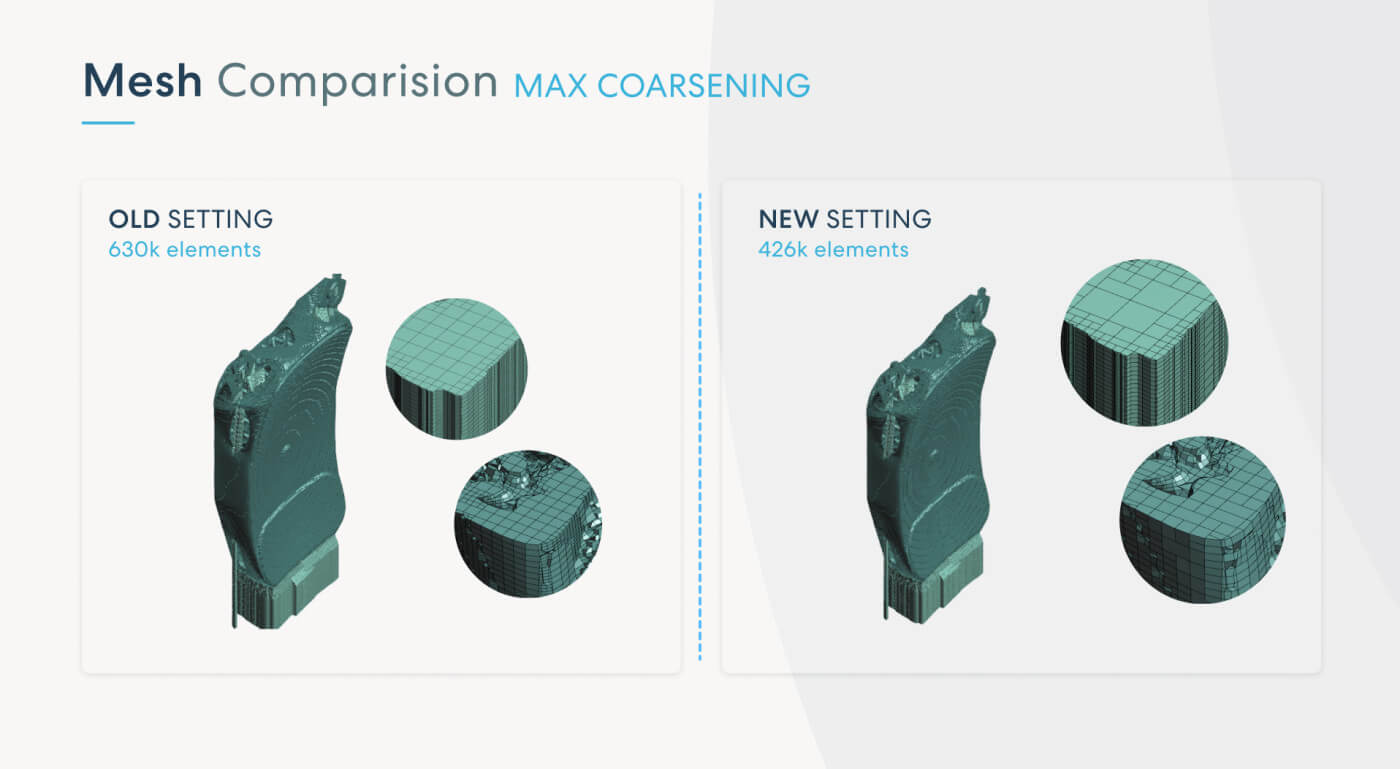

Finite element meshes often combine elements of different sizes. This adaptive meshing is a standard procedure in simulations and was implemented in Oqton's simulation engine from the beginning. What Oqton’s team achieved during AMFLEX was to enhance the adaptivity of mesh generation.

The goal is always to strike a balance between the computational effort and the accuracy of the simulation. We want to compute with a high degree of detail where it will improve process results, and save as much time as possible during design iterations and process preparation.

Oqton applied this new approach on a LPBF-made test part with impressive results. Computation time was reduced by a stunning 40% in the first tests, when the improved meshing capability decreased the number of elements from 630 thousand to 420 thousand compared to the previously used approach for adaptivity.

Oqton reduced the computation time of their simulation kernel Amphyon

Oqton reduced the computation time of their simulation kernel Amphyon

Next steps

The reduction in calculation time and the improved shrink line prediction will play an important role in the next stages of the AMFLEX project. OHB and the project partner Fraunhofer IAPT will use it to design a new opto-mechanical component for spacecraft instruments.

“The mirror to be developed within AMFLEX is a great candidate to test the simulation technology. It has delicate structures like the thin walls on the integrated mounting features that can be made with standard mesh parameters and thick segments where a coarse mesh might be more appropriate. This combination would benefit from improved calculation time,” Mulser concludes.

Both shrink line detection and advanced mesh adaptivity are lined up for the next releases of Oqton’s build simulation products.

John Schlasche

John Schlasche