Hybrid modeling – for a holistic approach to additive manufacturing

It’s easy to fall prey to the appeal of a one-size-fits-all approach. In additive manufacturing (AM), we see this in the unabating production of hardware and software that handle a single geometry representation or file format.

This complacence has led to many manufacturing dead-ends. Think of converting implicit geometries to meshes that result in GPU-crushing-file-sizes or the data integrity deterioration that comes with turning solid files into mesh. Yet we doggedly soldier on, creating files, converting files, from one machine to the next.

One way to circumvent this issue would be to accommodate all file formats and techniques in a single software. Imagine you create a part using various native geometries frictionlessly, and when the design phase is done and dusted, you send all the instructions to the machine from the same software. That’s exactly what hybrid modeling makes possible.

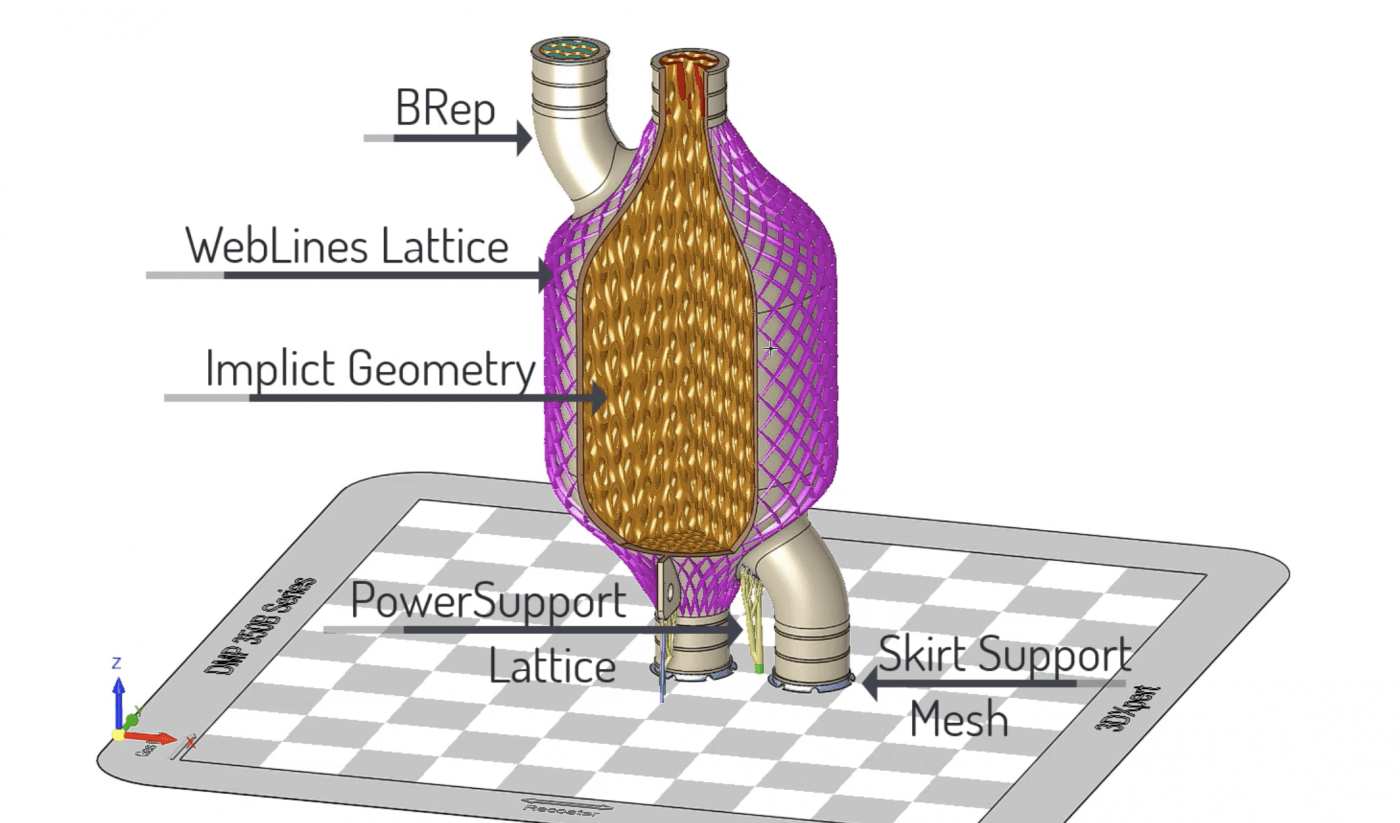

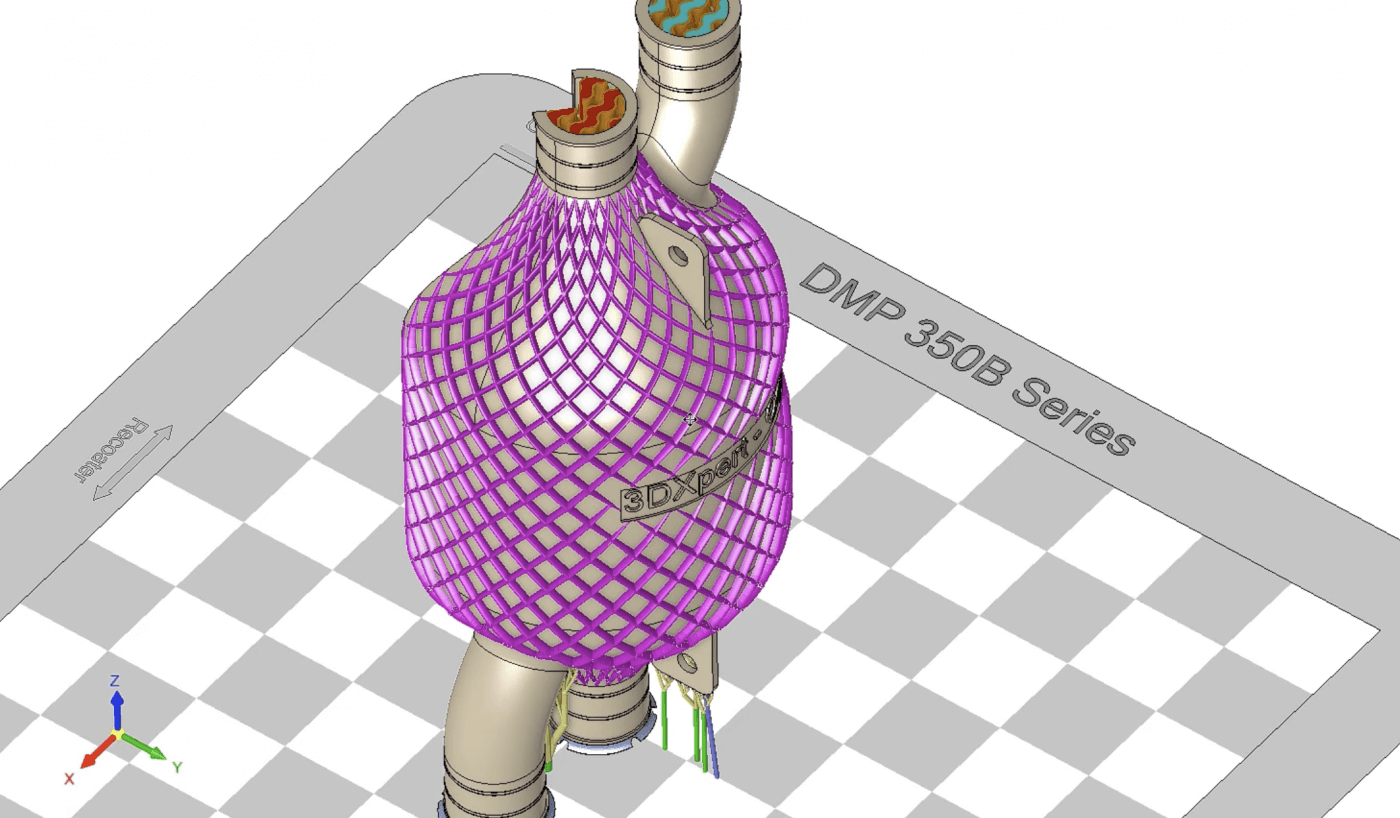

The term hybrid modeling describes the capability to combine different types of geometric representations to be edited and converted to printing instructions from their native format. Hybrid modeling allows you to use implicit representations for complex lattice structures and conformal ISO grid lines, solid (BRep) models for a smooth connection with intakes, meshes for patient-specific parts, or voxel grids for limitless geometrical formulations where other technologies struggle.

Quite an assortment of techniques. The sheer quantity seems to be at odds with the conventional belief that a single standard is best. As counterintuitive as it may seem, the undeniable fact of our industry is that parts manufactured using AM require various types of geometry representations. AM parts can include lattice structures or TPMS geometries or complex internal structures, channels, or very thin geometries – all of which demand high fidelity of the geometrical data.

Each geometry representation comes with distinct advantages and drawbacks compared to others, making it the best option for a specific situation. Some give you more accuracy, others deliver smaller file sizes. You’d be hard-pressed to find a way to design, slice and print these with one geometrical technique.

Hybrid modeling can get the best out of each technology without compromising user capabilities. It allows the creation of a single support system for a part composed of differently represented geometries, simulating the build process of all the geometries seamlessly, or slice holistically, still using appropriate underlying math for each.

You can find technology companies making bold claims about certain modeling types. Some wax lyrical about voxel modeling, a geometry frequently used in the visualization and analysis of medical and scientific data. However, voxels require you to sacrifice accuracy to achieve that smaller data size. Voxels are cubes, so if you want to create smooth boundaries on curves, you need to blow up the size of the grid to make it extremely small and numerous. In turn, the file size balloons to unmanageable scales. Works in theory, not in practice.

The new kid on the block, implicit modeling, is rapidly building an image as a “game-changer” in the additive manufacturing industry. Instead of representing geometry with triangles or boundaries, implicit modeling uses formulas that create the illusion of shapes. Some geometries are a natural fit for this modeling type, like lattices and gyroids, which have become emblematic of the power of implicits. The resulting file size is also impressively small.

The new kid on the block, implicit modeling, is rapidly building an image as a “game-changer” in the additive manufacturing industry. Instead of representing geometry with triangles or boundaries, implicit modeling uses formulas that create the illusion of shapes. Some geometries are a natural fit for this modeling type, like lattices and gyroids, which have become emblematic of the power of implicits. The resulting file size is also impressively small.

While implicits offer considerable advantages, they are not a silver bullet. Engineers have become painfully aware of implicits’ drawbacks in the latter stages of manufacturing when sending a design in form of instructions to a machine. Most machines work with meshes, and anyone who’s gone through the calvary of converting implicit to meshes knows that you end up with gargantuan file sizes.

This is a problem many AM customers are grappling with. Imagine you’re building a part for the aerospace industry. You’ll often find these are cylindrical shapes that are quite sizeable and use a lot of lattices. We’ve seen real-life examples where lattices resulted in 5GB output files, which almost no software was capable of loading.

Compare that with designing a part in Oqton’s 3DXpert, which has built-in hybrid modeling capabilities. You create the implicit geometry-based lattices inside the software and, instead of exporting them and moving them from system to system over several days, you simulate stiffness, and buildability and generate instructions in 3DXpert in two minutes.

Finally, the most common representation in CAD/CAM software systems are still BRep geometries and the vast number of designs for additive manufacturing use them. If you’d try to represent BRep or mesh data through implicits, your design would lose the sharp edges, resulting in poor accuracy. Overall, the conversion is an arduous, time-consuming process riddled with problems.

Instead of shoehorning designs into a single solution, why shouldn’t we work with many formats in a single software, editing implicits as implicits, BReps as BReps, meshes as meshes, and voxels as voxels? Hybrid modeling allows engineers to work with different techniques and to forget about the differences – and that’s what we call a truly holistic approach to additive manufacturing.

Kirill Volchek

Kirill Volchek