How Oqton’s AI-driven automation accelerates manufacturing

How do we innovate faster and increase production efficiency? This is today a burning question for manufacturers across many industries, from automotive and aerospace to consumer goods and energy.

At Oqton, we believe advanced Artificial Intelligence (AI) lies at the heart of the solution and we’re using it to pave the way for fast, flexible and entirely autonomous production with our Manufacturing Operating System.

Why is AI-based software the key to accelerating manufacturing? We know that hardware in its own right isn’t enough. We're at a unique stage of industrial development where we have more machines, which are faster, more specialised and more precise, than ever before. Yet long lead times are still crippling manufacturers’ ability to innovate, manufacturing execution systems are frustratingly inflexible and clunky, and productions are over-reliant on the manual execution of repetitive tasks.

We’re convinced AI can help and we have a dedicated AI team hard at work developing infrastructure and models that can fully automate the manufacturing process – from design to production to logistics.

Our AI has already upended the usual manner of working in 3D printing – a technology that is rapidly gaining ground across industries. Service bureaus, healthcare and consumer goods businesses are regularly using additive manufacturing technologies in high-mix productions. But each 3D printing job demands extensive file preparation – which has thus far mostly been manually performed by operators and technicians.

To simplify the additive production workflow, we’ve completely automated file preparation, and radically reduced reliance on manual intervention. This has had a powerful impact on dental workflows, with labs producing crowns, bridges, and aligners every day, completely autonomously with our Manufacturing OS. Currently, our AI automates these steps in an additive production workflow:

1. Part identification

When a user uploads a design file of a part into our Manufacturing OS, the software can automatically classify it into a pre-defined category. For example, a digital 3D design of a crown or a bridge falls into the dental category, while an impeller to the industrial category. For dental applications of 3D printing, our AI supports fine-grained categories such as bridges, crowns, or Removable Partial Denture (RPD) frames.

Getting the category right at the outset is crucial because it determines downstream tasks of automated file preparation. In other words, the routes that the part goes through in the platform depend on the correct initial identification.

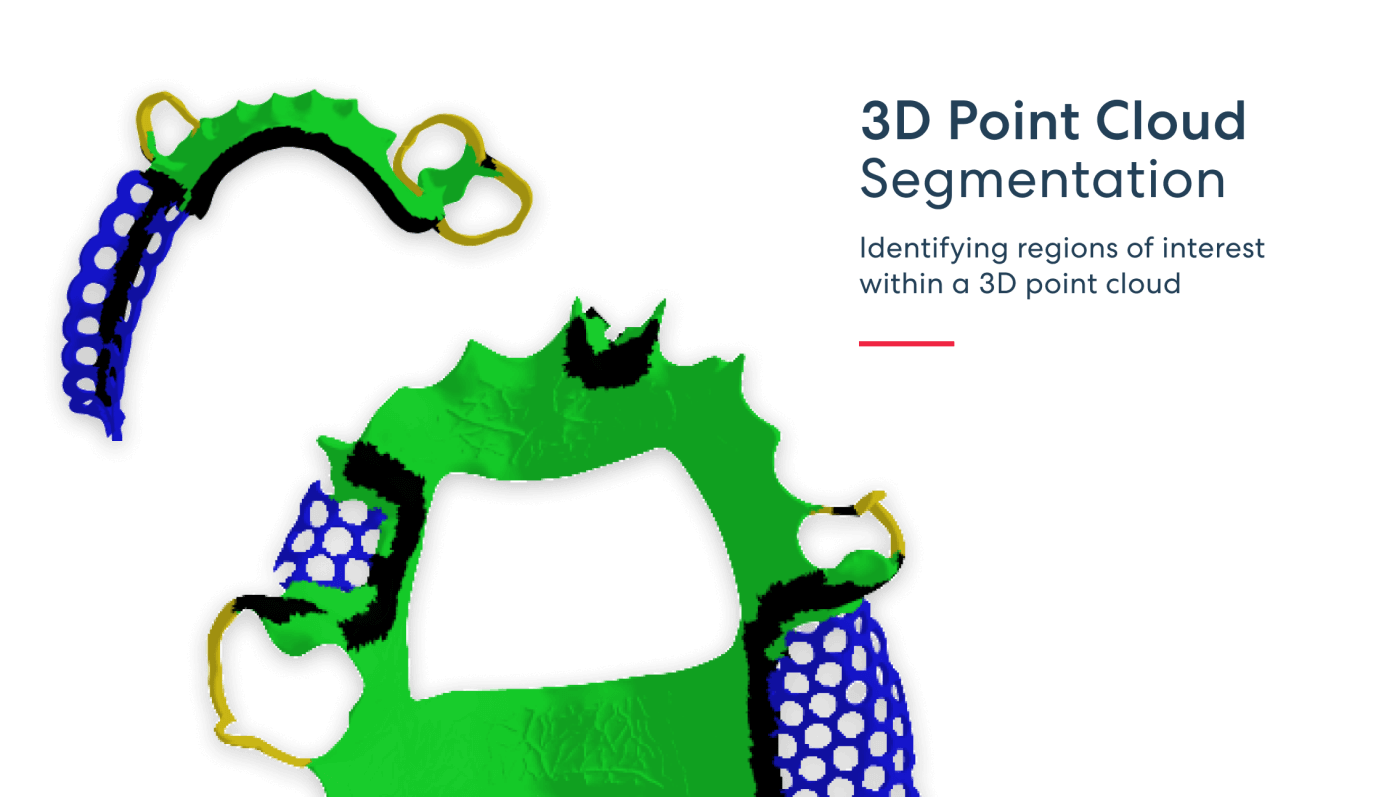

2. Part segmentation

Segmentation refers to AI’s ability to automatically identify regions of interest within a part. For example, for a dental bridge, an AI model can identify each individual tooth, or, the clasps of an RPD.

Correct segmentation has implications for another step in additive production – applying supports. Because in an additive process material is added layer by layer, parts require supporting structures to manage internal pressure and stop them from collapsing.

To address this challenge, we design support structures into 3D-printed parts. How we generate them depends on the region, and we aim to make this an automated process in the near future.

3. Part orientation

Before a machine starts printing a part, an operator must define its rotational orientation on the build plate, which impacts print speed, supports, surface finish, and the strength of the part. The benefit of Oqton’s Manufacturing OS is that its AI suggests different orientations to the user, and takes their preferences into account.

The orientation suggestions are based on similar parts a user previously oriented, of which we keep a historical database. Because the Manufacturing OS is cloud-based, we have fast access to a vast database.

Oqton’s AI also supports new users, who don’t have their own historical data, with a database of “reference” parts, which represent parts that a user would typically upload and which were oriented by our domain experts. This solution has provided exceptional support for technicians.

4. Nesting

To take full advantage of a printer’s build volume and lower costs, operators try to pack as many parts as possible into the machine during a process called nesting. Oqton’s AI model supports both 2D and 3D nesting for parts, which has boosted machine output.

A feature unique to Oqton’s AI is interlocked nesting, which allows dental technicians to fit an impressive number of RPD frames into a single build. Read about a dental production center in France that doubled the throughput of its metal printer with this feature on our blog.

5. Planning

In a manufacturing workflow, planning refers to the processes of assigning actions that need to be executed, such as parts to be printed, to a machine and operator. Planning is a knotty problem for AI because it involves myriad considerations, including machine and operator availability, due dates, dependencies – what task needs to be executed before another one – or right materials depending on the printer and the part.

In the pursuit to automate planning, we use a local search-based AI approach, which involves trying to efficiently identify interesting combinations of actions, machines and operators, to ultimately identify the combination that minimizes the makespan or delivers the parts just in time.

Automation of these steps has translated into enormous productivity gains in healthcare, and, as we broaden the types of data we analyse – 3D point clouds, sensor data, audio data, and imagery – we’ll see the same effect in other industries. We’re not getting there overnight, but by continuously exploring and applying the latest advancements, we’ll transform manufacturing.

Find out more about Oqton's AI Academy.

Tom Tourwé

Tom Tourwé