Building a common language – The role of 3MF files in additive manufacturing

Interoperability, or the ability for hardware to talk to each other, is crucial to automating additive manufacturing.

A range of different file formats exist in today’s 3D printing landscape, and they can vary from one machine and software solution to the next. In the process of designing and manufacturing a single part, a user will transfer files between hardware and software solutions. Engineers and technicians will import geometries, lattices, and nests from other build preparation & design software into 3D printers. And the machines and software need to communicate.

The 3D Manufacturing format, or 3MF, was created with the aim to establish a common language in additive manufacturing. A 3MF file captures all the information necessary to print a 3D model accurately using any mix of applications, platforms, services and printers. In other words, 3MF files offer broad compatibility and interoperability, giving manufacturers much greater freedom and flexibility.

The 3MF file solves the well-known issues with STL files, which do not include an accurate three-coordinate representation of the model or any information about its color, texture or material. It was developed as a free, open source format by the 3MF Consortium, which includes key industry players like HP, Microsoft, Hexagon, EOS, SLM Solutions and many others.

The result is a relatively small file that captures much more 3D model data than any other format and moves additive manufacturers closer to the ultimate goal of printing any object on any brand of printer using any software application.

Oqton uses 3MF as a standard for communicating with printers, as well as to exchange information with other software. It is useful because it can handle 3D geometries, lattices, colors, and slices, enabling the end customer to move all types of information between different systems, software, and hardware.

Understanding the 3MF file

Because it was designed with additive manufacturing in mind, a 3MF file can store a relatively large amount of data. It is essentially a CAD file with complete information about a 3D model, or everything needed to understand how the product should look and function. This includes:

- Color and texture data

- Material data

- Part description, copyright, designer

- Thumbnail images

- Support structures

- Beam lattices

- Scene scale and measurements

- Tray support

- Printer configuration

The existing standard for 3D printing is the STL file, created in 1987 for stereolithography CAD software. It describes the surface geometry of a 3D model via tessellation, but this is not a consistently accurate representation. It is more of an approximation that can result in printing errors unless manufacturers spend a lot of time cleaning up the STL file prior to output. In addition, STL files are very large while 3MF files are compressed to be very small.

There are other file formats suitable for additive manufacturing, such as OBJ, VRML and FBX. But like STL, these were not developed for 3D printing and lack a complete set of data about the 3D model. Support for these formats also varies considerably across software and printing platforms.

How to create and edit 3MF files

The 3MF Consortium keeps an updated compatibility matrix that includes all of the software, additive manufacturing hardware, and service bureaus that support 3MF as part of the 3MF ecosystem.

Many 3D printing software support 3MF, including Oqton’s 3DXpert. These solutions enable you to create a 3MF file as easily as a 3D model. You can also convert an existing STL file into a 3MF file by simply opening the STL file and exporting it as a 3MF. The steps are similar to any other “save as” function.

To edit a 3MF file, you will need a separate tool. However, because Microsoft belongs to the 3MF Consortium, it has made 3MF files natively compatible with the Windows operating system. As a result, you can preview and edit 3MF files with Windows-based tools like Paint 3D, among others.

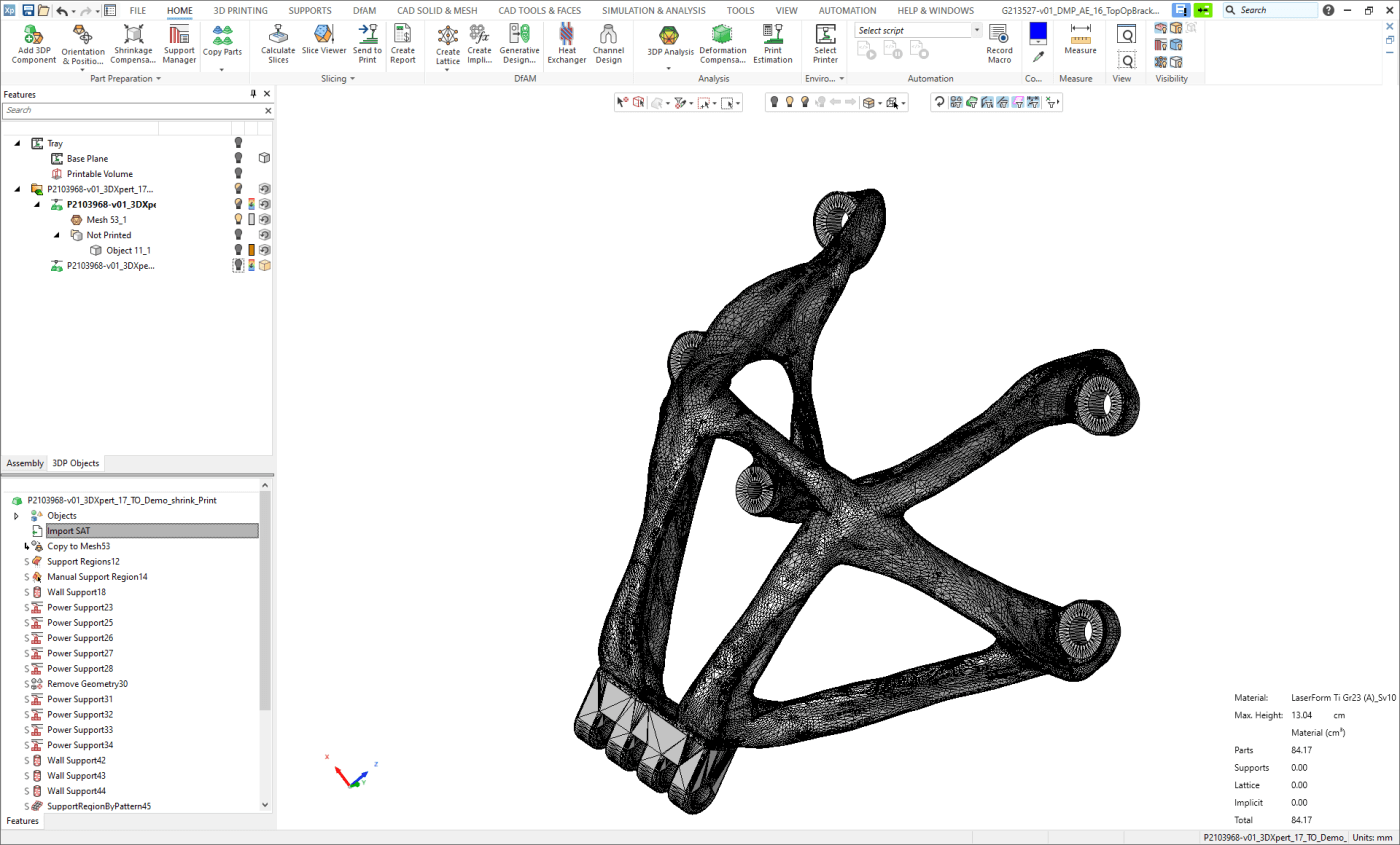

3MF file of a bracket imported into 3DXpert

3MF file of a bracket imported into 3DXpert

3MF files in additive manufacturing

With 3MF files, design software can deliver full-fidelity 3D models that are compatible with many other applications so one file can be used from design to fabrication. Right now, a 3MF file can be used in simulation, design for additive manufacturing (DfAM) software, nesting tools, additive manufacturing workflow platforms, manufacturing execution systems (MES), and others.

3MF is also widely supported due to the number of additive manufacturing companies in the 3MF Consortium. It is compatible with virtually all major CAD tools, slicers and 3D printer manufacturers.

The benefits of using 3MF files in additive manufacturing are clear, and they exist because the format was designed to make 3D printing as efficient as possible. These advantages include:

Completion

3MF files include all model, material and property information in a single archive, making file sharing easier and eliminating the need for printer-specific slicers. With 3MF files, a designer can build a 3D model in a CAD application and include print parameters, supports and part orientation, so the file can be printed with any device that supports 3MF.

Precision

3MF files include clear definitions of printable mesh requirements, which makes it impossible to create an unprintable file and dramatically reduces the risk of print errors.

Security

3MF supports data encryption and other security features that are helpful for medical device, military and other applications that are heavily regulated.

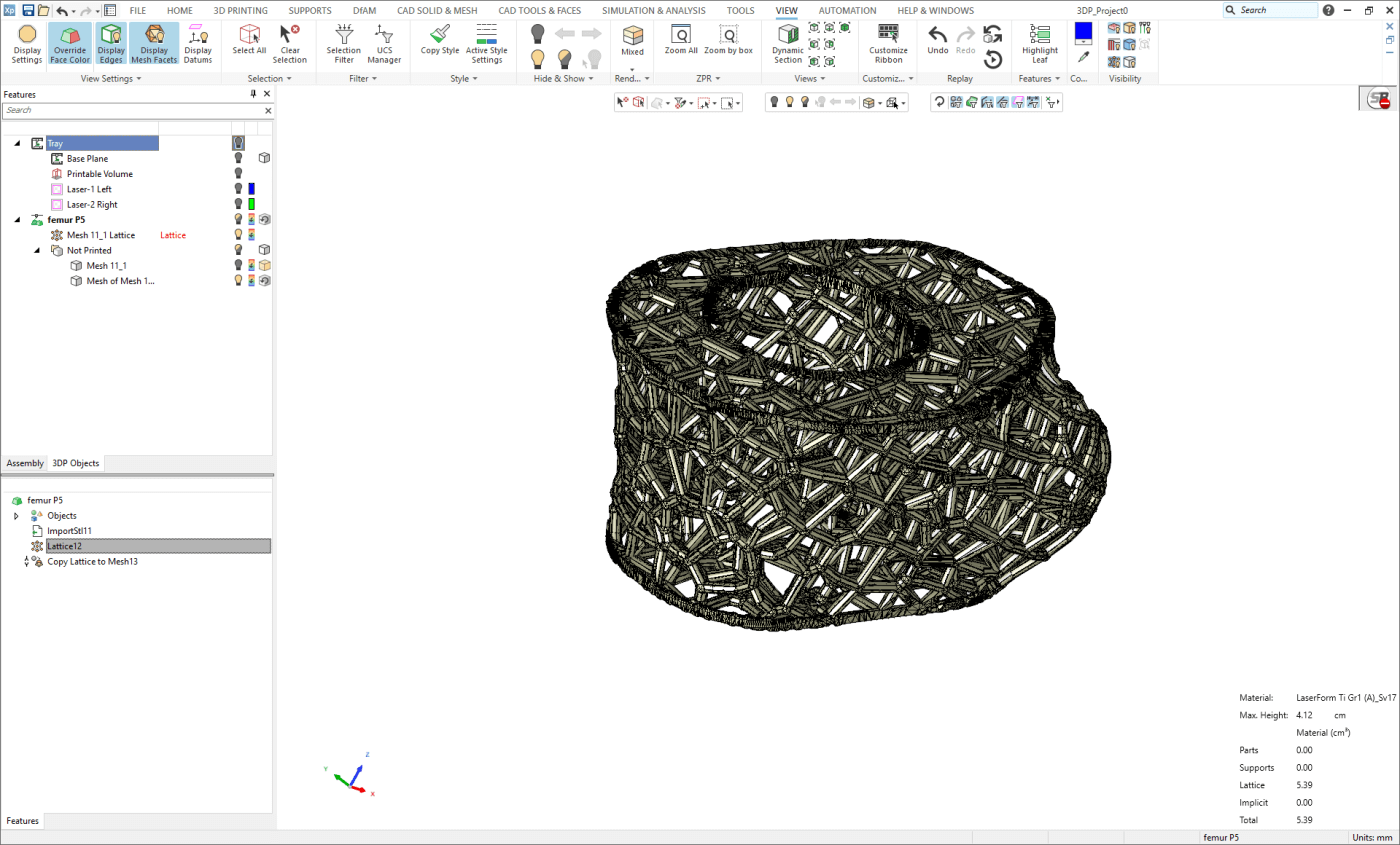

A 3MF file of a femur implant piece, with lattices, in 3DXpert

A 3MF file of a femur implant piece, with lattices, in 3DXpert

Conclusion

3MF files solve critical interoperability challenges in additive manufacturing, enabling designers, engineers and manufacturers to work more efficiently and generate more accurate results. As new tools for additive printing emerge, they can build in 3MF compatibility and further extend the interoperability of the format.

Oqton uses 3MF files as it makes it vastly easier for customers to use different brands of software and 3D printers, and combine CAM, MES, and IOT in one brand-agnostic platform. Ultimately moving to a common industry standard, as a 3MF, would reduce interoperability challenges, and enable more organizations to leverage additive manufacturing.

Marta Matvijev

Marta Matvijev