With Oqton, we can put all our machines onto one platform. It's much easier for us to use now, on a daily basis. We can do more, and more easily.

Maxime Fontaine

Manufacturing Manager, Crown Ceram

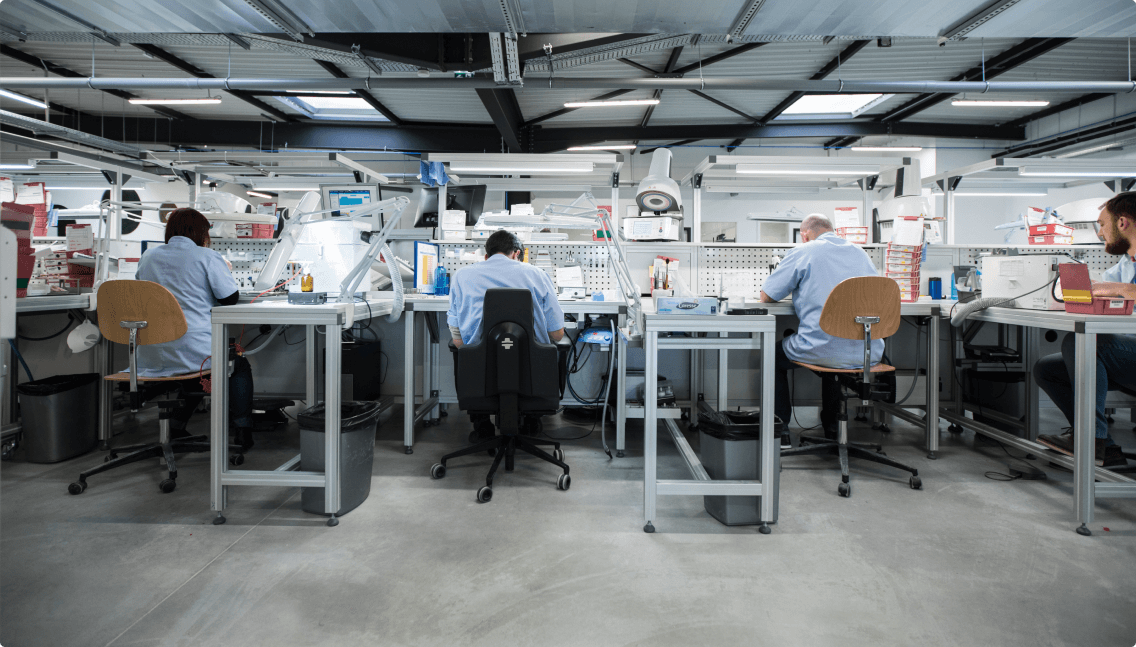

They continue to innovate to constantly offer reliable and accessible solutions and prospects that guarantee quality. Crown Ceram offers a wide range of products and has a close collaboration between prosthetics, engineers, and dental practitioners.

Their decision to switch to Oqton software a year ago has, by their own admission, totally transformed their way of working. “Everything is easier for us now”, enthuses manufacturing manager Maxime Fontaine, in charge of milling, 3D printing and the upgrade of Crown Ceram’s 3D printers, “and the cost savings are insane!”

With 120 employees, Crown Ceram is purely focused on the dental market, making dental prosthetics to order based on an impression of the patient. They continue to innovate and remain on the cutting edge of this rapidly developing technology by investing in the latest innovations. With the arrival of 3D printing onto the market around ten years ago, says Fontaine, “we decided to digitize every prosthetic we made: we digitize a model and then we design the new tooth and manufacture it with a 3D printer and milling machine.” This is followed by a manual finish to precisely color match the final product.

By the end of 2019, they had grown to eight milling machines, five 3D printers for resin and three 3D printers for metal, with many different makes and models. “Every time you needed to have a specific software for each machine because each brand of machine has their own software”, says Fontaine. “It's very hard for the team to be an expert on every software, with specific workflows on every machine”. This is why, at the start of 2020, Crown Ceram decided to partner with Oqton.

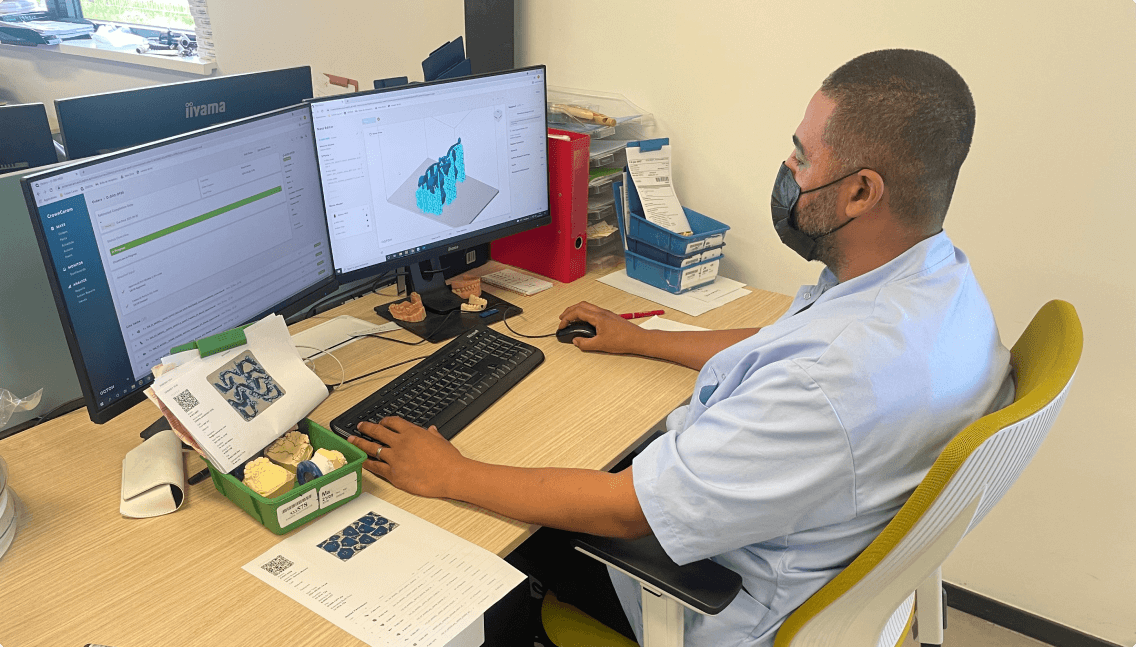

“With Oqton, we can put all our machines onto one platform. It's much easier for us to use now, on a daily basis”, says Fontaine. Since the partnership, productivity is far higher, and the complexity of the projects they can take on has increased too. “We can do more, and more easily. The productivity of our 3D resin printers has improved by 30 percent, so we don't need to buy a new machine now. On our metal printers we have reduced the human time necessary to create a plate by four.”

With Oqton, we can put all our machines onto one platform. It's much easier for us to use now, on a daily basis. We can do more, and more easily.

Maxime Fontaine

Manufacturing Manager, Crown Ceram

Overall, Fontaine believes they have been able to double their output since shifting to Oqton. Crown Ceram had considered purchasing two additional machines next year under the previous system; now, they don’t have to. Given that each metal printer costs around €300,000, the cost savings for them have been substantial.

“We print the same things as before, but faster”, says Fontaine. “A lot faster. So we can put more parts in one plate because they can do something like 3D nesting for RPD frames, with more parts on one build. And the printing time is very fast.” The impact on profitability is therefore “simple math”, he says: “Because when you print only 20 parts per day on one machine, you take the monthly price of the machine and divide it by 20. Now, we can divide it by 40 parts per day.” When they need to buy a new machine, it will now be like “buying one but getting two”.

This also provides a cost saving with regards the necessary business square meters. With each machine requiring nine square meters floor space, half the number of machines requires half the amount of business space. “Everything is cut in half, including maintenance costs, if productivity is multiplied by two.”

Since partnering with Oqton, Crown Ceram has been able to increase profitability, which improves their position in the market, but also to scale the business to take on more clients. Due to the fast growth of the French dental market, Fontaine admits they previously had to ask their sales team to slow down, because their machines and software could not keep up with demand. Now, “we tell the sales reps they can send us as much as they want!”

Operation time of data preparation for the RPD frames used to require one hour to build ten parts. “Now I think it takes 15 minutes”, says Fontaine. With the old software, it was difficult to break the support from the part, with one person dedicated to this manual process; “now, you can remove it with just one finger because the supports are much thinner”, laughs Fontaine, “and it is maybe 99 percent complete, you only need to do some light finishing. The two processes cannot be compared. It was a big problem, and now it’s very easy.”

The initial decision to team up with Oqton, however, required a change in mindset, as the previous software came free from the manufacturer, while Oqton is subscription based. “As soon as I saw the first print on the machine and the huge gap in terms of productivity, I didn’t mind paying an annual subscription compared to having to buy a new €300,000 machine”, says Fontaine. When you combine that with the savings on human times and materials, he says, the annual subscription is in fact a huge net saving compared to the previous ‘free’ software: “Yes, we have to pay for it, but we save so much more.”

In particular, Fontaine is a big fan of the updates on the Oqton dashboard: “It tells you how many parts you will print today, the quantity of resin this will use, real-time machine status, you can see charts to see if production is ramping up, and if the material usage is ramping up or down. All of this is clear to see, in one place.” Not only that, but some of the CAM software was last updated in 2015. By comparison, he says, Oqton is unique as updates happen every two weeks on the cloud enabling them to stay on top of the rapid pace of change: “there is no competition right now.”

Continuous improvements by Oqton translate into additional benefits and upgrades for Crown Ceram. “The goal of Oqton is to automate the most you can. At the beginning, we were doing more manually, and now we are doing less and less manually. So, we have time to do other things in the lab.” His advice for other companies in the same position is to talk with Oqton, “because there are huge savings to be made, you feel it instantly. The only question you have is why didn’t we do this sooner?” And his advice for his direct competitors? “Please, don’t use Oqton!”, he laughs, “They are too good!”

Crown Ceram is a family business that has cultivated its art of innovation for more than 38 years. They continue to innovate to constantly offer reliable and accessible solutions and prospects that guarantee quality. Crown Ceram offers a wide range of products and has a close collaboration between prosthetics, engineers, and dental practitioners.