Oregon-based Metal Technology (MTI) has over 40 years of experience in metal manufacturing and has garnered a strong reputation among its clients due to its wide range of capabilities and high quality outputs. MTI serves a variety of customers in aerospace, defense, nuclear, and medical applications with both high and low quantity production runs relying on proprietary deep-draw forming, forging, spinning, CNC machining, and additive manufacturing methodologies.

Along with a client list that includes NASA, what really makes MTI standout is its ability to manage extremely complex designs and answer the stringent requirements of working with specialized materials such as nickel superalloys, tantalum, and titanium.

Additive manufacturing: a world of new possibilities

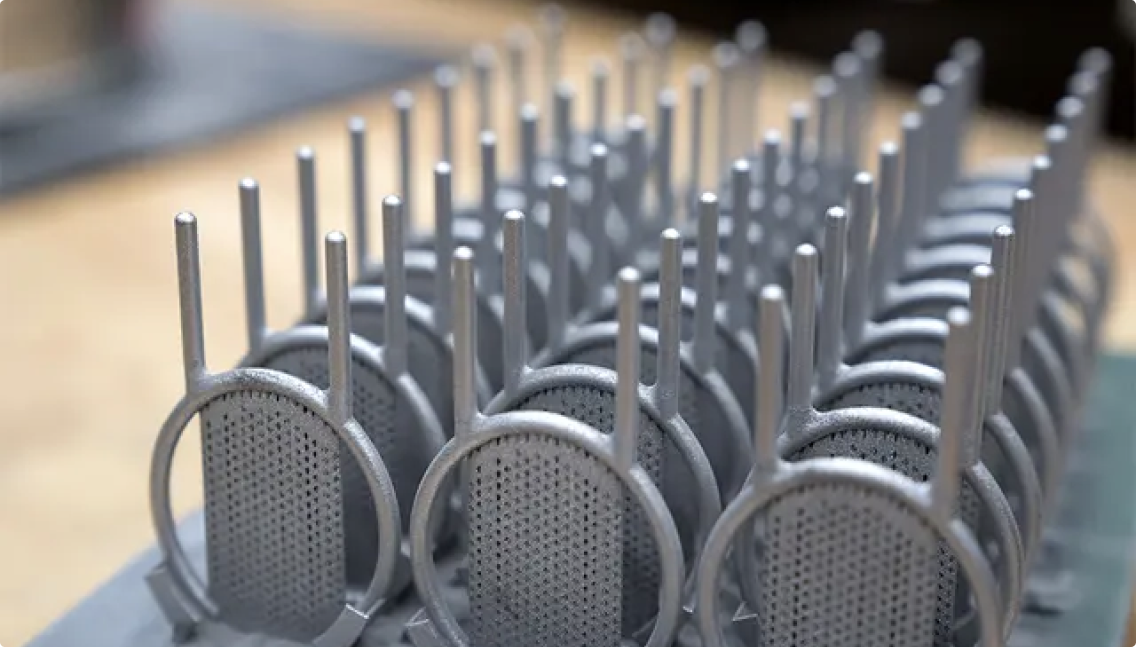

As a keystone of the company’s effort to reshape how metal parts are made, MTI took the leap into additive manufacturing. In short order the company’s work was recognized by the Pacific Northwest Defense Coalition, who chose Metal Technology as a winner of the 2016 Innovation Award for its work to develop additive manufacturing techniques for refractory metal components for U.S. Navy missile propulsion systems.

“We work closely with our customers to understand their challenges, identify solutions for their complex requirements, and then build components to fit their special needs,” explains Jason Stitzel, Director of Engineering at Metal Technology. “We look at additive manufacturing—in this case Direct Metal Printing (DMP)—as a strategic capability that gives us the unique opportunity to develop parts with added functionality together with our customers.”

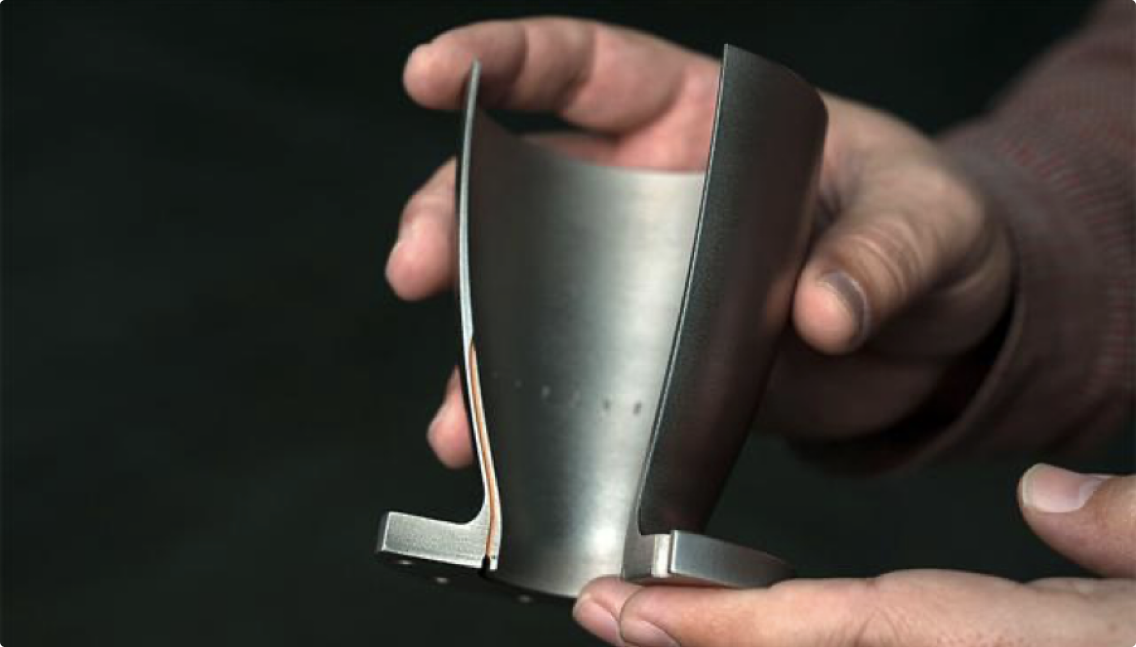

“One recent case illustrating the benefits of additive manufacturing of metal parts was related to a valve component with several intricate internal passages. Traditionally, the valve would be manufactured in pieces that would be welded or braised together. Using 3D printing, MTI worked with the customer’s team to create an equivalent design in a single piece. In addition to saving the time and labor associated with assembly, developing a single piece print enabled MTI to deliver a better quality product that will require less maintenance and have a longer lifespan, says Stitzel.

“Beyond cost savings and complicated geometries, additive manufacturing enables innovative builds with key materials. “Many of our projects require materials like nickel superalloys and tantalum, and we felt that additive technologies would enable us to offer our customers better solutions to the unique challenges related to working with these materials and the extreme temperatures involved.”

3DXpert for workflow efficiency and optimized printing

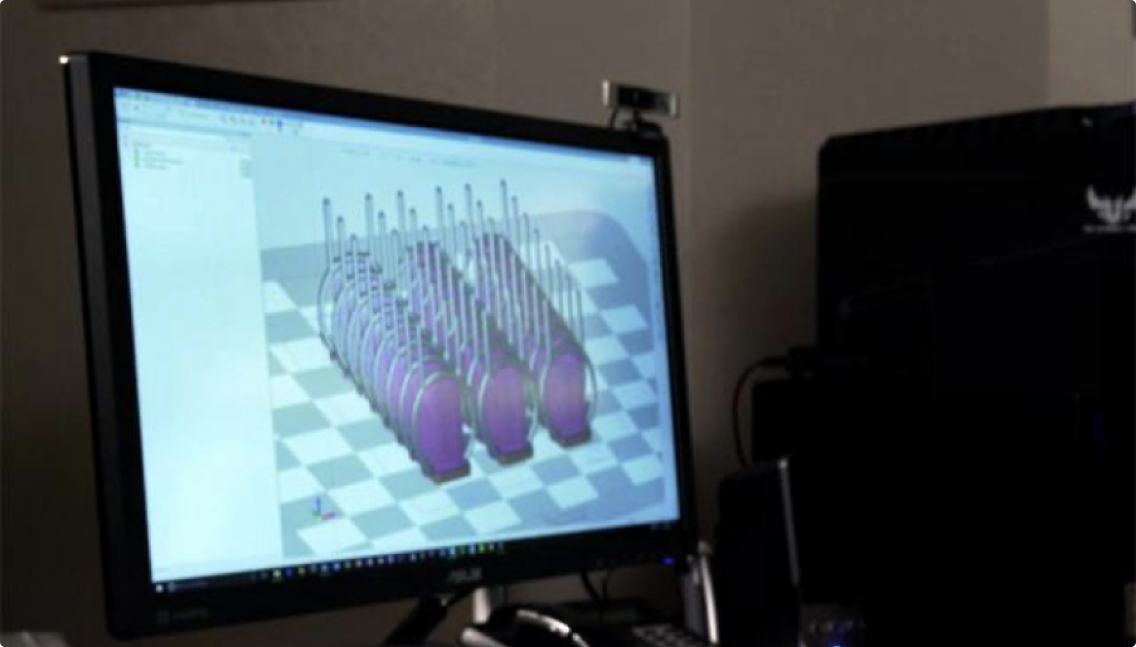

Always looking for a new edge, MTI was eager to incorporate 3DXpert™ software—the industry’s first comprehensive solution for metal additive manufacturing.

“We went from using at least three different software systems to get the final product to doing it all with one,” said Stitzel. “3DXpert gives us all the tools we need to produce geometries and files that our 3D printers can understand and use in production in a single package. It removes the need to convert from a solid model to an STL, a process that inherently introduces issues and errors. Instead, we just pull the native CAD model directly into 3DXpert, modify it with CAD tools if we need to, and apply the support structures.”

“Beyond the efficiency of working with a single software package, 3DXpert’s patent pending 3D Zoning capability has enabled MTI to increase productivity by 40%. “We can use 3DXpert’s zoning capabilities to easily define different printing strategies for different areas,” explains Stitzel. “We can build a very thin shell that has fine 30-micron layer to give us a really good surface finish; and then we can build the rest of the part that doesn’t require that level of finish in 60-micron or 90-micron layers and achieve almost identical mechanical properties. This may be possible with other software, but it would take a lot of effort. With 3DXpert it’s quick and easy. 3DXpert also allows us to better analyze and plan the part, so we can use less support and less material which further reduces cost and time.”

Eliminating the bottleneck of print file preparation

Keeping the 3D printers running is critical to MTI’s business. “When our machine is sitting idle because it doesn’t have a build file to run, we’re losing money,” said Stitzel. “3DXpert enables us to do things much quicker, which is important for us and for our customers.”

3DXpert can reduce file processing time by as much as 75%, which was quick to make a difference at MTI.

Before we used 3DXpert, running a complicated part through a slicing engine took close to 20 hours to process, slice, run the parameters and create a build file. With 3DXpert, we could do the same build in just four hours. Now we can receive files on a Friday and get them started over the weekend rather than delay to the following week. With our previous workflow, that just couldn’t happen.

Jason Stitzel

Director of Engineering at MTI

Taking the pain out of design modifications

When the part you are making is mission-critical and the requisite material is expensive, you want to get things right the first time. “Quite often we might notice something at some point in the process and want to go back and change a detail in the design to make the part better, or help us produce it faster and cheaper. In the past, any changes to the model meant we had to start over from scratch. 3DXpert is much more tolerant to design and orientation modifications. We may need to tweak some things, but we don’t lose all the work we’ve done. That’s an advantage that makes 3DXpert really stand out for us, because now we can go back and make the part better without risking significant delays or cost overruns for the project,” said Stitzel.

Up to the challenge

“We pride ourselves on serving a very unique and demanding customer base with extremely challenging requirements,” said Cosmer. “With additive manufacturing , we can produce any geometry that a customer may dream of, allowing us to provide customers with solutions that they could not have access to in the past.”