How it works

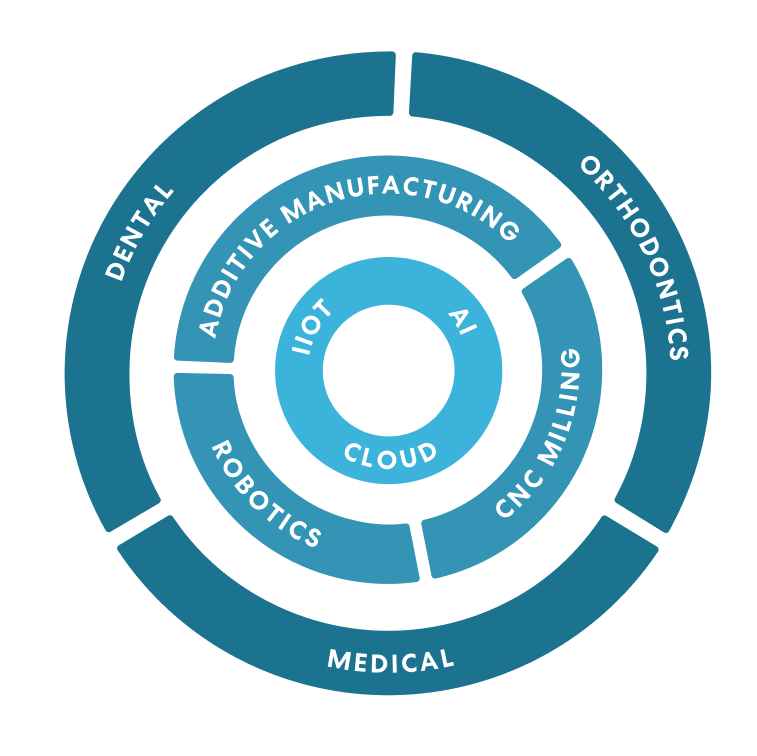

Increase manufacturing automation, utilization, visibility, traceability, and scalability. The Oqton Manufacturing OS provides your organization with a unified user experience that deploys artificial intelligence across your end-to-end engineering and production workflow for significant process efficiency gains.

1. Artificial intelligence

- Automate manually repetitive tasks with artificial intelligence to increase the utilization of your workforce and assets, and increase process scalability.

2. MES

- Configure your production environment across machines, materials, and production routes for real-time status tracking and visibility across your processes and workforce. Capture a complete historical record of your production actions, and increase utilization through process analysis and optimization.

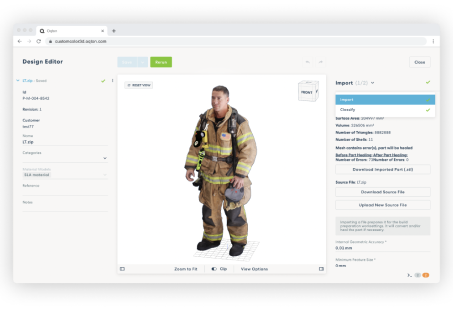

3. Build preparation

- Prepare builds within the Manufacturing OS for additive manufacture. Powered by artificial intelligence, you can capture expert preferences, knowledge, and experience to copy similar and historical setups previously used in your organization, including part orientation, support generation, nesting, slicing, and build process simulation and compensation.

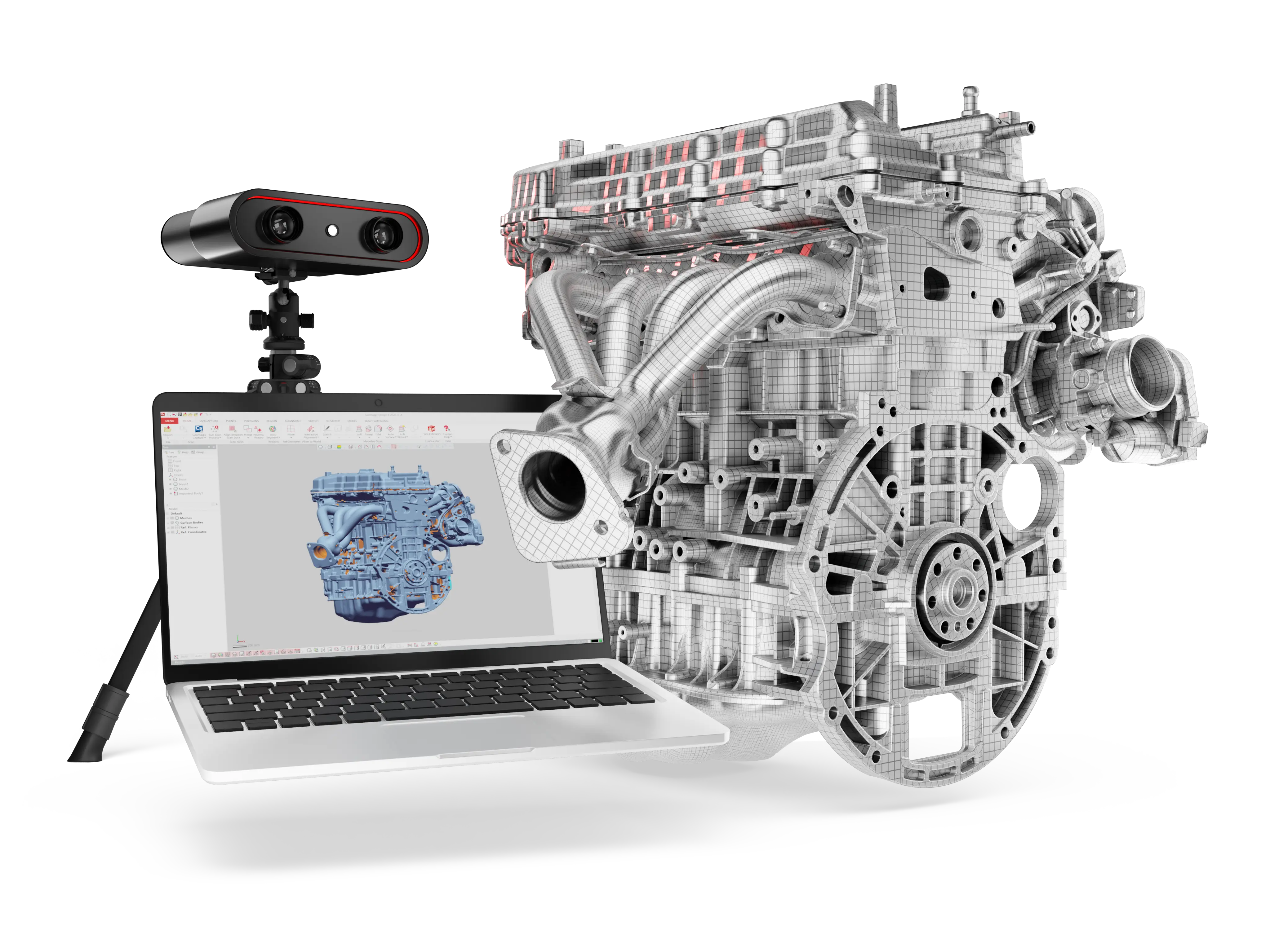

4. CAM

- Automate your CNC milling workflows for hybrid additive manufacturing.

5. Industrial IoT (IIoT)

- Monitor machine sensor data in real-time and visualize data through configurable dashboards. Optimize your OEE by automating anomaly detection and alerts, and synchronize your IoT and MES data for full traceability.

6. Cloud connectivity

- Secure access and visibility to data across distributed production environments with a SOC2 Type II certified, commercial cloud solution. Combine stringent and configurable security controls with the ability to quickly scale across different sites and departments in your organization through personalized roles-based security access, eliminating the need for multiple disconnected software programs.