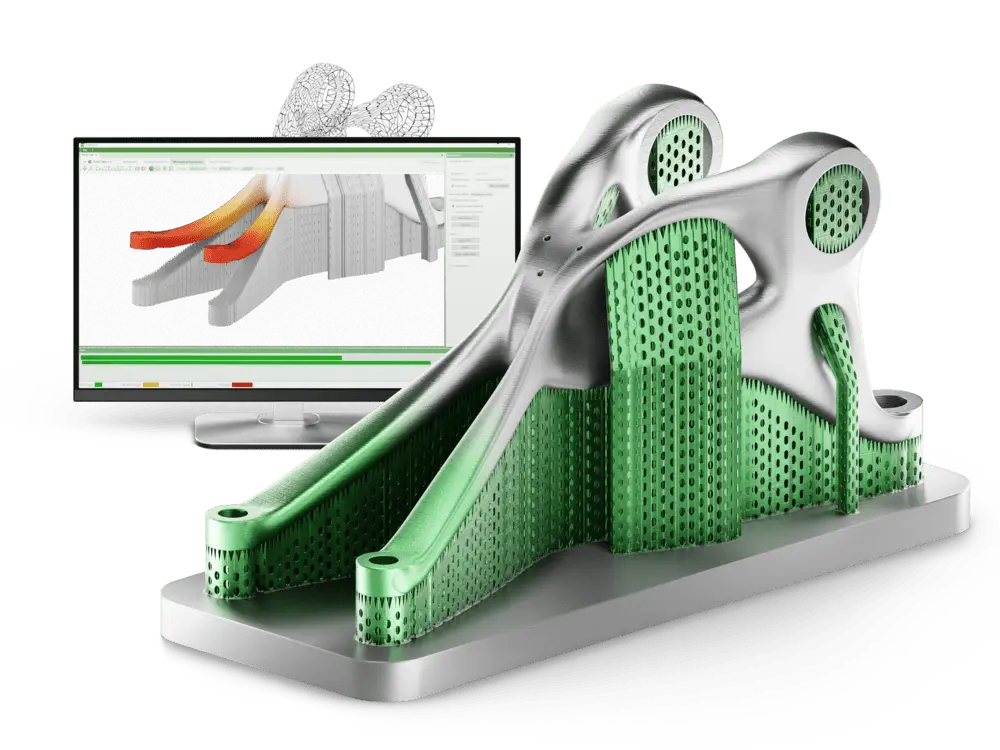

The ASAP Principle

The ASAP-Principle describes four ideal steps on the way to a stable, efficient and reliable process chain: Assessment, Simulation, Adaption and the Process itself. By examining all possible build-up orientations with respect to economical and physical aspects of the process on the Assessment stage, both, limitations of the design and optimal orientations can be calculated. The integration of simulation based, automatic generation of optimized support structures and fast process simulation tools into the pre-processing chain on the Simulation stage ensures geometric accuracy and increases process stability while tremendously reducing the costs of process preparation. Finally, on the Adaption stage, process parameters should be controlled with respect to thermal and mechanical aspects via hatch re-orientation and parameter adaption. After going through these steps of pre-processing, on the last stage the first-time-right process itself concludes the ASAP-Principle.

- Assess build time, material use, accessibility, post processing efforts and distortion sensitivity for all build-up orientations of your 3D model.

- Automatically perform a fast calculation of residual stress and distortions of your component on regular workstation hardware.

- Adapt scanpower/-rate and scan-vector alignment based on local geometry and optimize the thermal input and strain accumulation according to cutting edge scientific knowledge.

- Build your part first-time-right.