Industrial Additive Manufacturing Software

Design, prepare, schedule, manufacture and track with additive manufacturing software from Oqton.

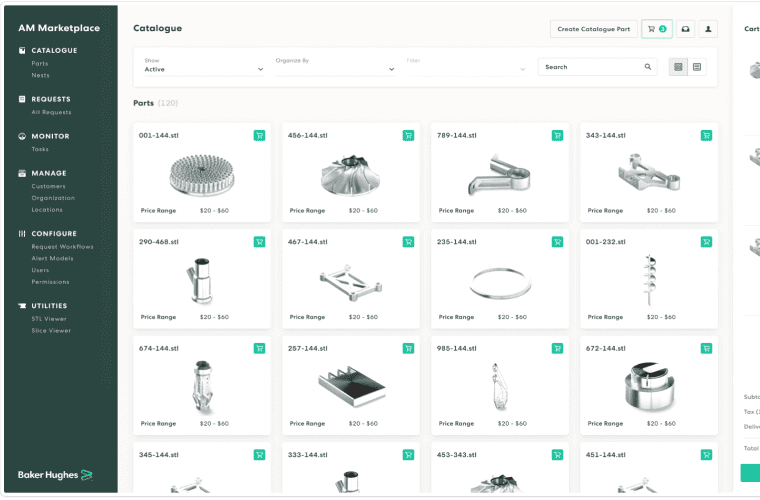

Oqton and Baker Hughes Enter Commercial Agreement

Oqton and Baker Hughes, an energy technology company, will form a technical and commercial agreement to offer a comprehensive software suite for production-scale additive manufacturing in highly regulated industries.

Trusted by customers across many industries

How are Additive Manufacturing technologies influencing production of the future?

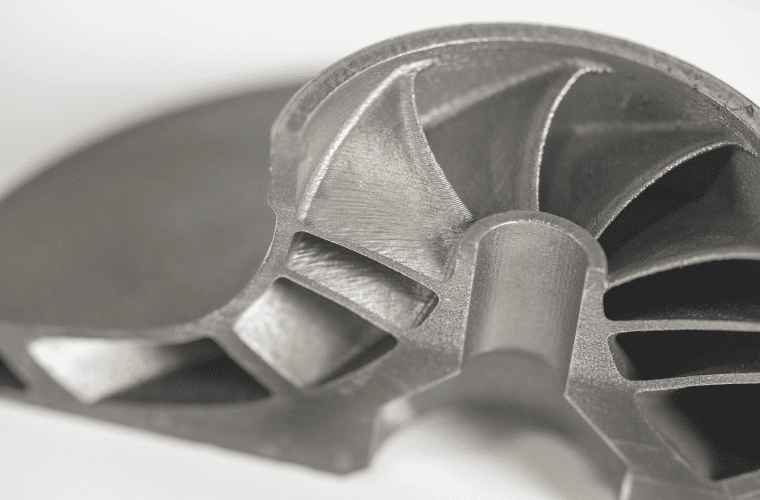

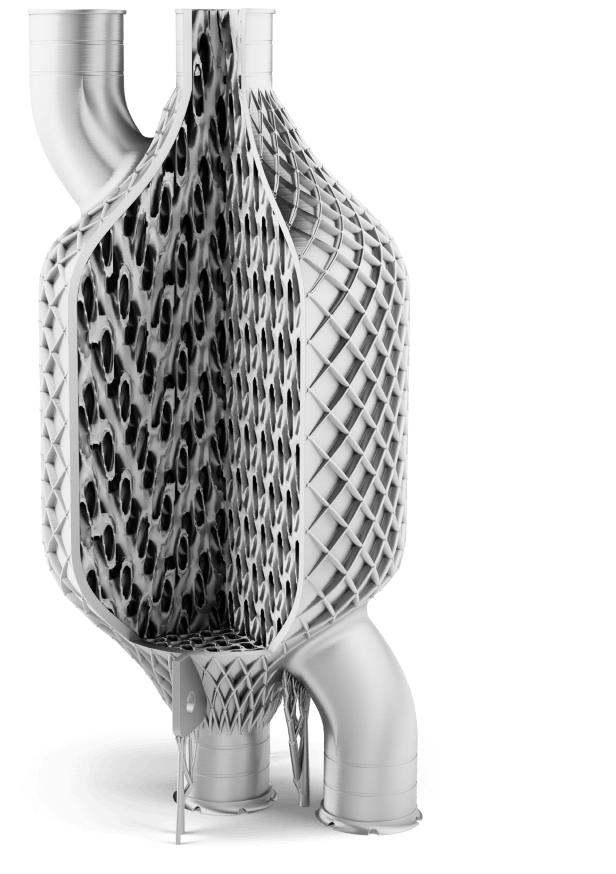

- Additive Manufacturing technologies are playing a pivotal role in shaping the production of the future. Additive Manufacturing, also referred to as 3D printing, builds parts layer by layer, producing parts quickly and cost effectively. This process offers a greater level of design flexibility, enabling the production of parts with complex geometries that would be difficult, if not impossible to achieve using conventional techniques.

- The Additive Manufacturing process can offer a number of advantages over traditional manufacturing methods, including:

- Reduced lead times

- Lower costs

- The ability to produce parts of greater complexity

- Enhanced process sustainability by reducing waste through the reuse of materials.

- The use of Additive Manufacturing technologies is revolutionizing the way industrial products are manufactured. Companies across aerospace, automotive, energy generation and consumer products are able to produce lighter, stronger and more efficient parts with incredible precision.

Want to learn more about how Oqton technology can accelerate your Industrial Additive Manufacturing?

How can we help?

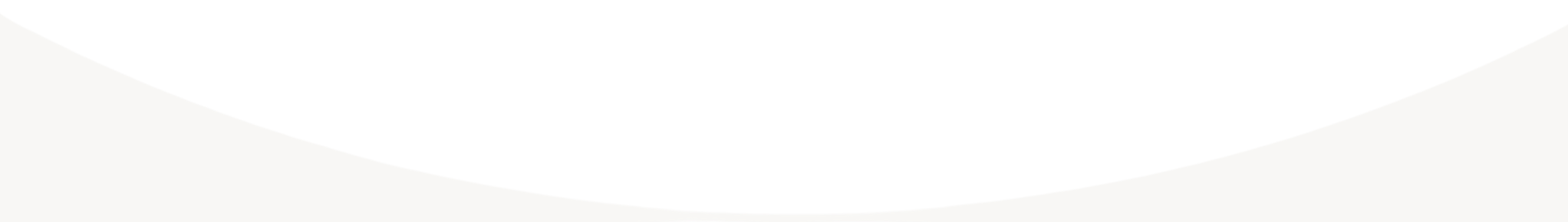

Design for Additive Manufacturing

Additive Manufacturing technologies have unlocked the ability to build almost any geometry. As part complexity increases, so does the requirement to Design for Additive Manufacturing to ensure sustainable production. Oqton’s Industrial Additive Manufacturing solutions enables:

- Access to dedicated toolsets, including implicit modeling, to easily create the most complex geometries.

- Design decisions to be made based on manufacturing process constraints to ensure consistently successful builds.

- Creation of lightweight, manufacturable structures, to address challenges across industries such as aerospace, automotive and energy.

- Optimization for stiffness, heat transfer and boundary conditions.

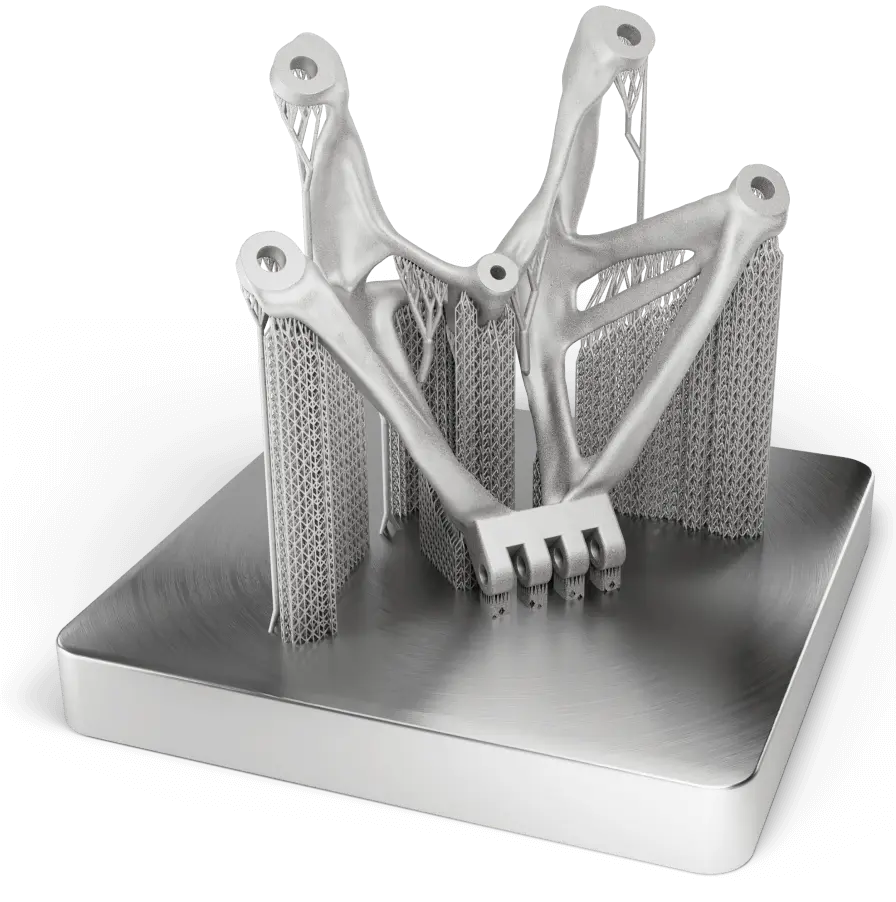

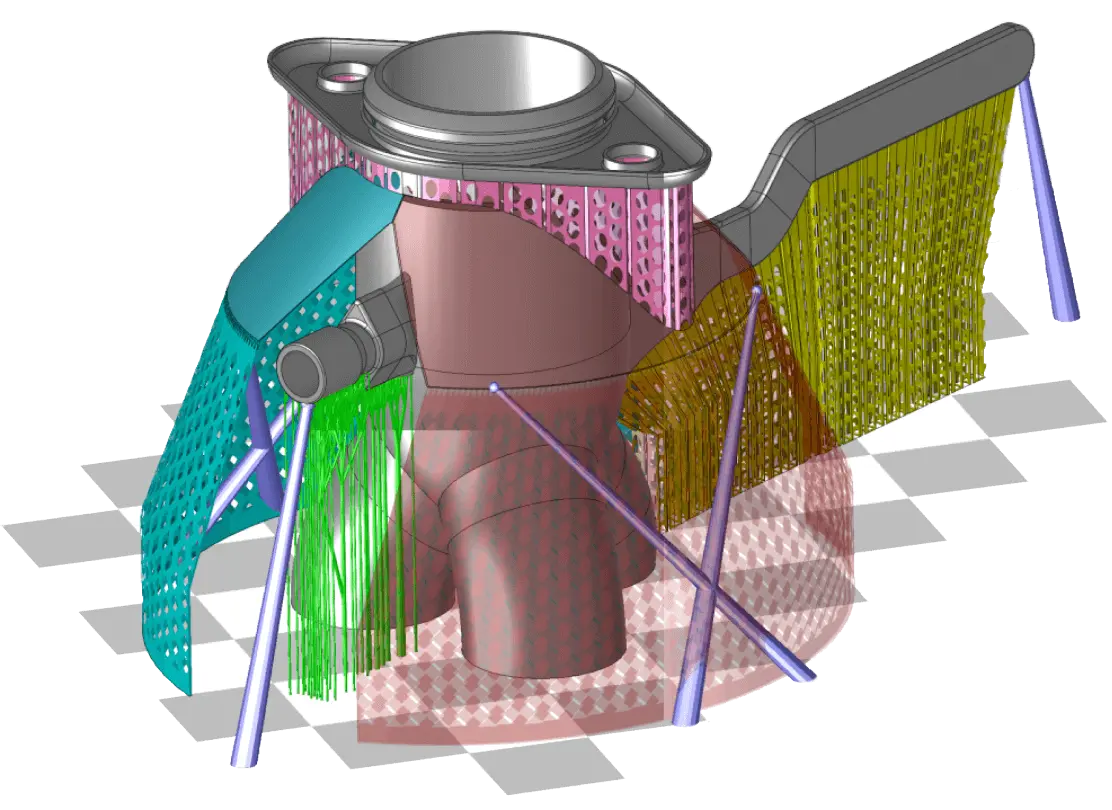

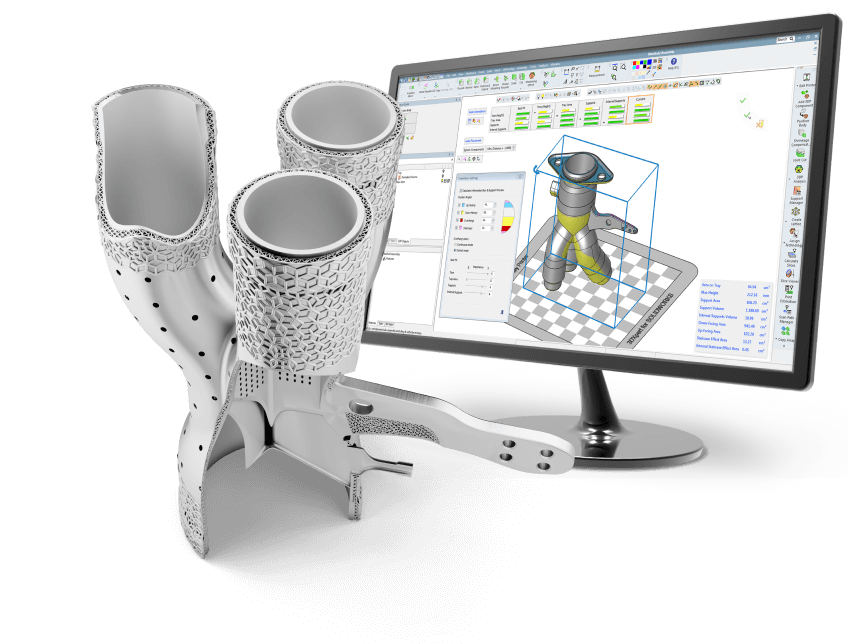

Prepare

One of the greatest challenges for a successful build process is being able to prepare a part that results in a stable and consistent build. Reduce costly iterations on the journey to your first article and streamline your production with tools built by engineers, for engineers:

- Dedicated build preparation tools to optimize the printing process.

- Parametric geometry creation, including support structures, for complete control over parts of any complexity.

- AI-driven tools to capture and automate gathered expert knowledge.

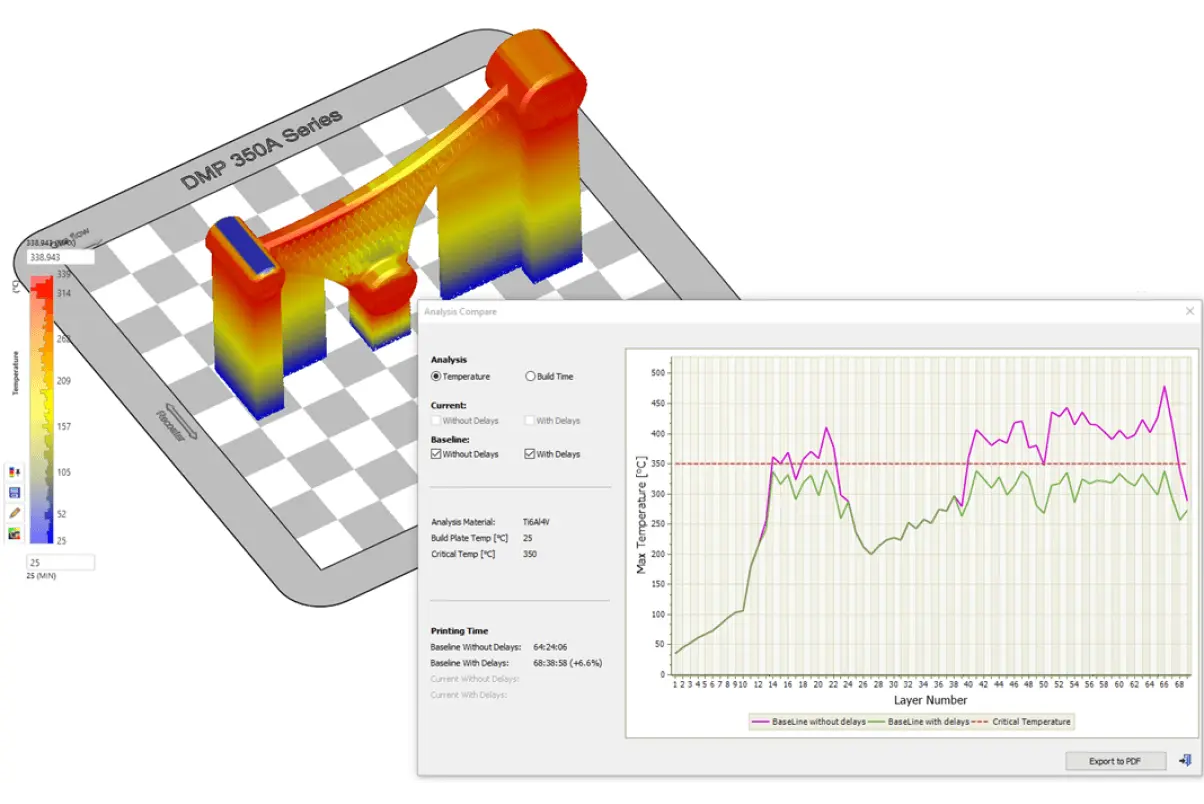

Simulate

Detect and prevent costly build failures by simulating mechanical stresses and thermal conditions inside the build chamber, and address issues during the build preparation.

- Predict displacements and deviation from desired dimensions and pre-compensate your parts to print right the first time.

- In the rare cases where further iterations are required, use 3D scan data of your as-built part as input to adjust geometry automatically.

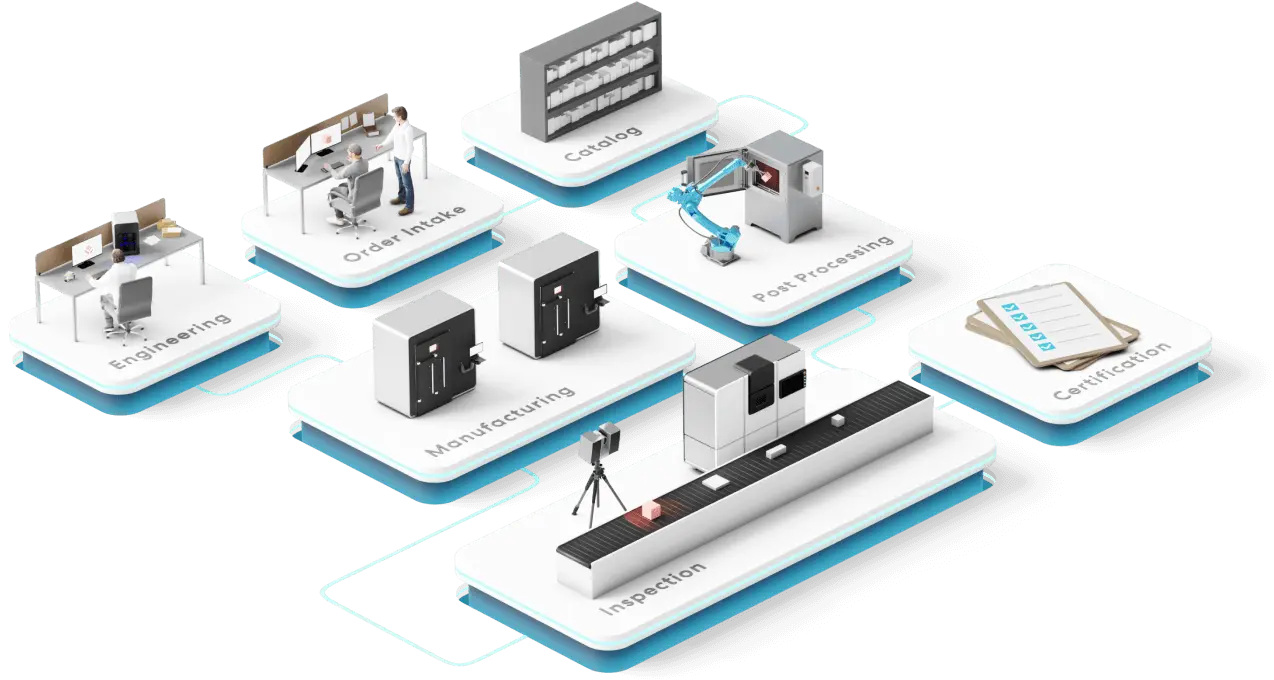

Execution

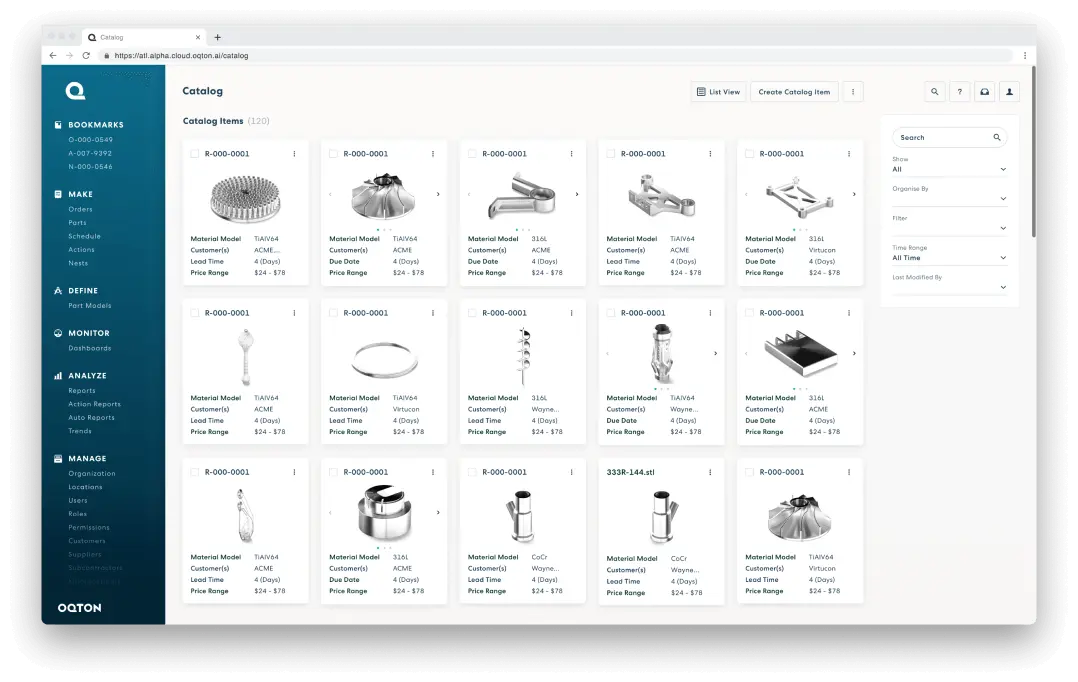

Manage and optimize your AM workflows. Minimize costly machine down-time by configuring your production environment across machines, materials, and production routes for complete visibility using:

- Digital Catalog and Customer Portal

- Order Management / MES

- Planning and Scheduling

- Material Management

- Monitoring and IoT

- Integration with ERP

- Real-time machine sensor data monitoring

- Configurable dashboards for data visualization

- Automated anomaly detection and alerts

Repeatable Manufacturing

- Enable repeatable manufacturing in highly regulated markets.

- Capture part specifications, testing requirements and the complete manufacturing workflow in a Digital Product Definition.

- Ensure consistent quality across multiple printers, materials and locations through enhanced real time monitoring capabilities.

Discover how Oqton's Industrial Additive Manufacturing solutions can revolutionize your production process

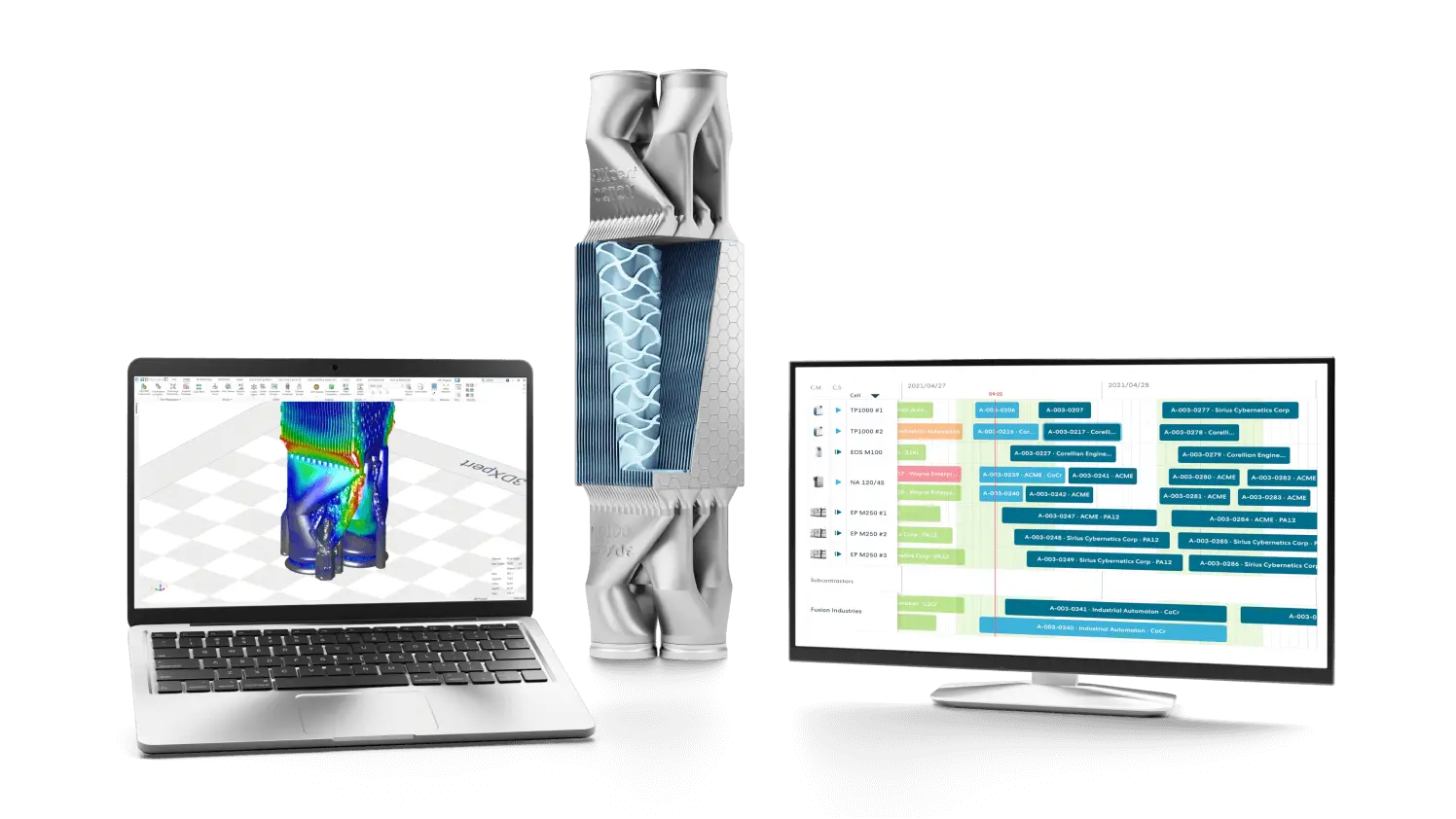

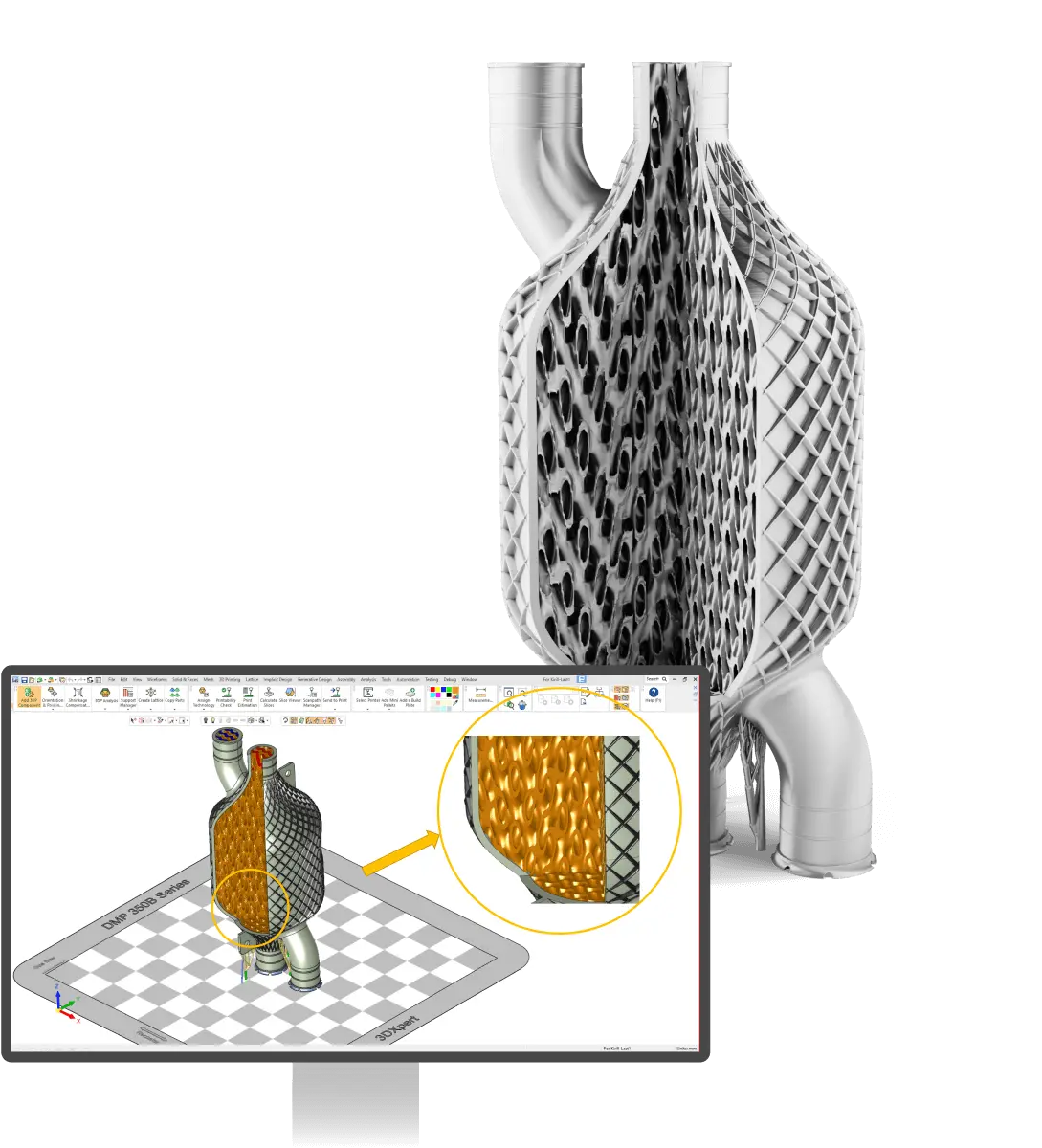

All-In-One Industrial Additive Manufacturing Software

Prepare, optimize, and 3D print high-quality parts in record time with 3DXpert, an all-in-one, integrated 3D additive manufacturing software that streamlines the complete workflow, from design to printing.

Automate Your Production With Software Powered By AI

Open and intelligent solution for high efficiency manufacturing with automation and total control of your production that connects applications across design, CAM, 3D printing, monitoring, and inspection.

Hear from our customers

“After switching to 3DXpert, we could take on more projects and put more engineering time into them because we have more time available. We’ve achieved a 20% efficiency increase across the board, and this is most noticeable on larger parts or bigger quantities within a build.”

David Buschemeyer

Additive Engineer, ADDMAN

“3DXpert streamlined our process and workflow greatly. We eliminated a ton of in-and-out of software operations, which has helped us reach our goals of maintaining top data integrity and eliminating redundancy from our workflow. Beyond that, the support we have gotten from the 3DXpert team is simply first-class.”

Tom Gabriel

R&D Manager, Emerson Automation Solutions

“Our agreement with Oqton will support the industrialization of our additive manufacturing and help drive more intelligent operations for the energy and industrial segments.”

Jim Apostolides

SVP Enterprise Operational Excellence, Baker Hughes

Trusted by industry partners

The sky is the limit.

Manufacture anything with Oqton Industrial Additive Manufacturing solutions.

FAQs

How can I request a demo of Oqton’s Industrial Additive Manufacturing solutions?

Click on any of the request a demo buttons on this page, and fill in your contact details. A member of our team will then contact you and if eligible will provide you with the installation and licensing information.

What are the advantages of Additive Manufacturing for Industrial applications?

The Additive Manufacturing process offers numerous advantages for industrial applications, such as:

- Improved design flexibility

- Faster prototyping

- Shorter lead times

- Greater customization

- Cost savings through reduced waste

- The ability to produce high quality products fast

Additive Manufacturing eliminates the need to outsource production and reduces costs associated with design, labor, shipping, and production.What industries does Oqton’s Industrial Additive Manufacturing Solution serve?

Oqton address Additive Manufacturing challenges across many highly regulated markets, with solutions that adhere to all relevant security and standards. These industries include Aerospace, Automotive, Oil & Gas, Energy, Defense, Space, and many more.

Oqton’s Additive Manufacturing solutions also serves service bureaus and contract manufacturers for those industries.What are the benefits of a cloud based Industrial Additive Manufacturing solutions?

Oqton’s Additive Manufacturing Solutions enable unlimited scalability of your solution as your business grows. Unlike enterprise software solutions, you can start with a solution that fits to your requirements at the time, with a view to connect more printers, machines and users as you grow.

Other benefits:

- No more time and resource consuming manual hardware or software updates.

- Complete and secure environment that backs up your entire dataset to the cloud.

- The ability to link different sites to the same account, to alloow more strategic capacity planning.Is Oqton Manufacturing OS secure?

Oqton’s cloud solution is SOC2 and NIST 800-171 compliant. It is also compliant with GDPR. Upon request, we are happy to provide all the necessary approvals and certifications.

What types of Additive Manufacturing does Oqton’s Industrial Additive technology support?

The Industrial Additive Manufacutring solution supports a broad range of Additive Manufacturing technologies, including:

- Laser Powder Bed Fusion (LPBF)

- Electron Beam Melting (EBM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF)What Additive Manufacturing materials does Oqton’s Industrial Additive technology support?

Our Additive Manufacturing solutions support a broad range of materials across metals and polymers.

What 3D printers do Oqton’s Industrial Additive solutions support?

Both 3DXpert and the Manufacturing OS support printers across the following hardware manufacturers:

- EOS

- 3D Systems

- SLM Solutions

- Xact Metal

- HP Multi Jet Fusion

- Stratasys

- Trumpf

- DMG MORI

- Renishaw

- Farsoon

- Nexa3D

- Additive Industries

- Eplus3DAre 3DXpert and Manufacturing OS integrated?

Yes, 3DXpert has a tight integration with Oqton’s Manufacturing OS. The integration of both Additive Manufacturing technologies allow for seamless download/upload of files, support structure and build preparation automation workflows, and more.

Why should I use Oqton’s Industrial Additive Manufacturing solutions in my workflow?

Running an Industrial Additive Manufacturing production site has many unique requirements and challenges. Our Industrial Additive Manufacturing solutions will help you manage your resources, orders and planning to make sure you have complete traceability, monitoring and view of your entire factory.

Where can I get technical support for Oqton’s Industrial Additive Manufacturing solutions?

For 3DXpert, a comprehensive list of FAQs and support articles can be found on our Knowledge Base.For the Manufacturing OS, please contact us, and we will answer any question that you have about our solutions.