3D Scanning Solutions

Maximize the potential of your 3D scanning hardware with our industry leading Reverse Engineering and Inspection professional 3D scanning software portfolio.

Unlock the value of your existing parts with Geomagic software.

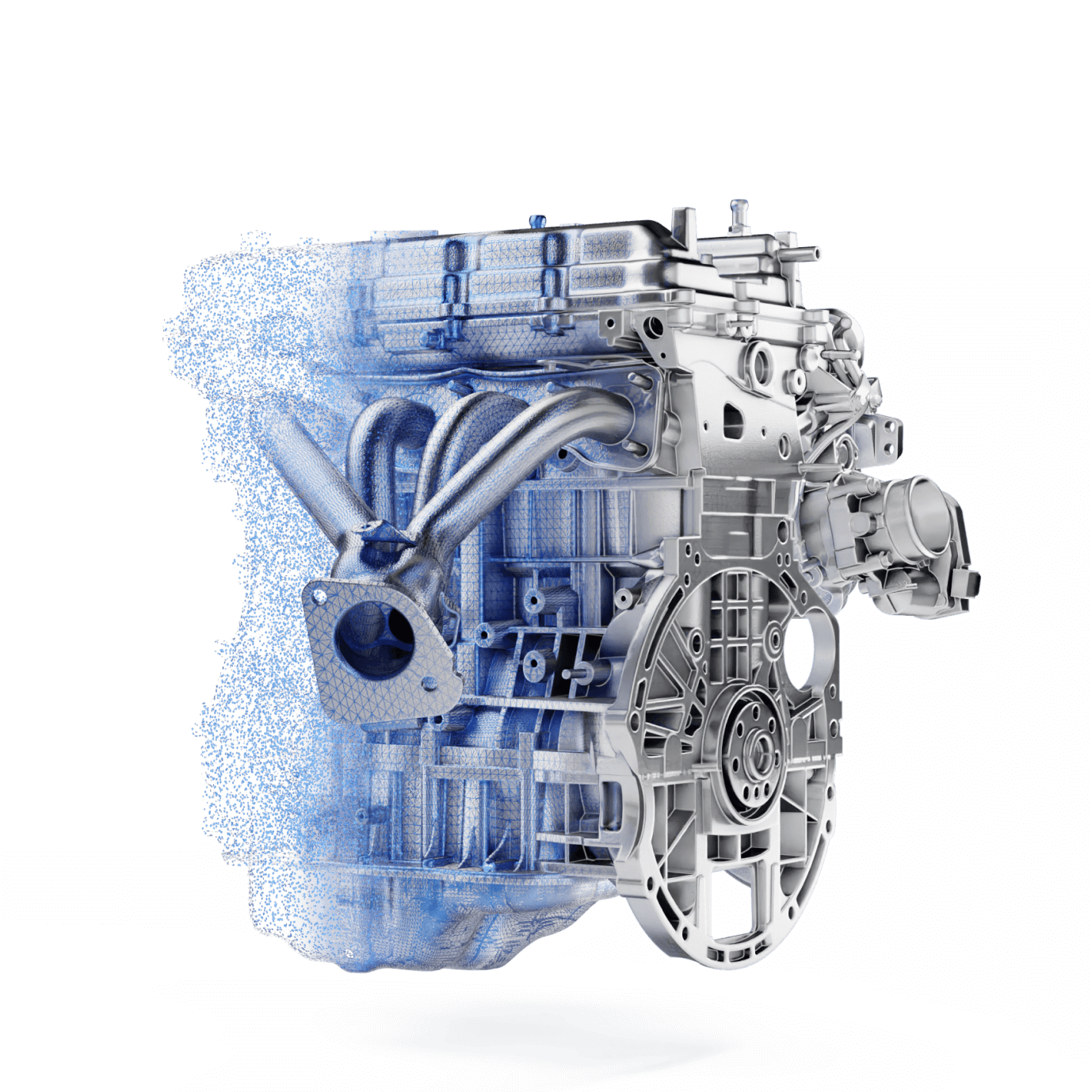

3D Scanning is the process of converting physical, real-world objects into precise digital models, for various applications.

Integration of 3D scan-based technology into any production environment provides the perfect platform to supercharge product manufacture through fast digitization, geometry optimization and accurate quality assurance.

Reverse Engineering

Reverse Engineering has always been used in part production in some capacity, to redesign, recreate and optimize components.

Whether you're recreating a legacy part from 3D scan data, or taking your prototype to mass production, we've got the solution. No digital CAD file or design data for an existing part? Reverse Engineering is the answer.

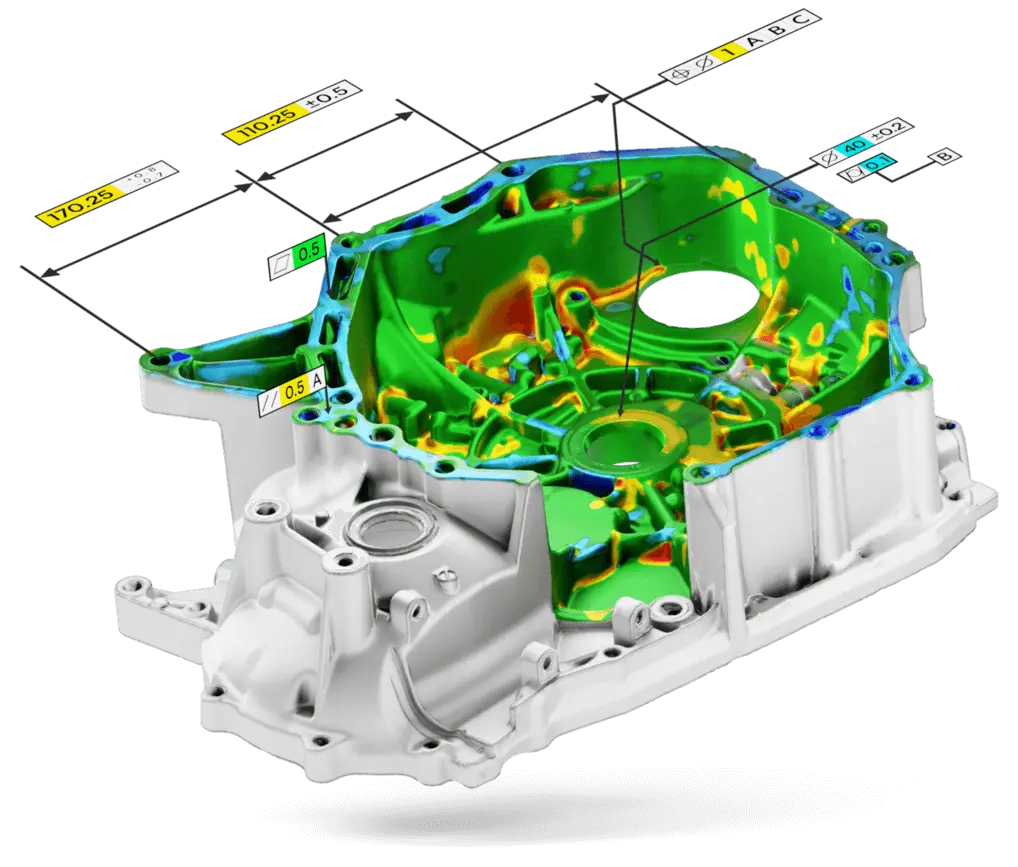

Inspection

If you're serious about producing high quality parts, regardless of what industry you're supplying, then high quality 3D scan-based inspection software are a non-negotiable. Pairing an accurate 3D scan-based inspection software with a quality, accurate 3D scanner will set you up for success.

Hardware agnostic solutions for any industry

Fast, accurate, 3D data capture, CAD creation and inspection is revolutionizing industries across the board, from aftermarket automotive parts and aerospace assemblies, to cultural heritage preservation and dental aligner inspection.

Whatever your industry, whether complete novice or seasoned 3D scanning veteran, our hardware agnostic software packages have you covered.

Customer stories

Learn about some of the game-changing ways our customers are using 3D scanning to bring better products to market, faster.